Researchers at Flinders University, along with teams around the globe, have made a big leap in sustainable construction by developing a new type of concrete.

This isn’t just any concrete, though.

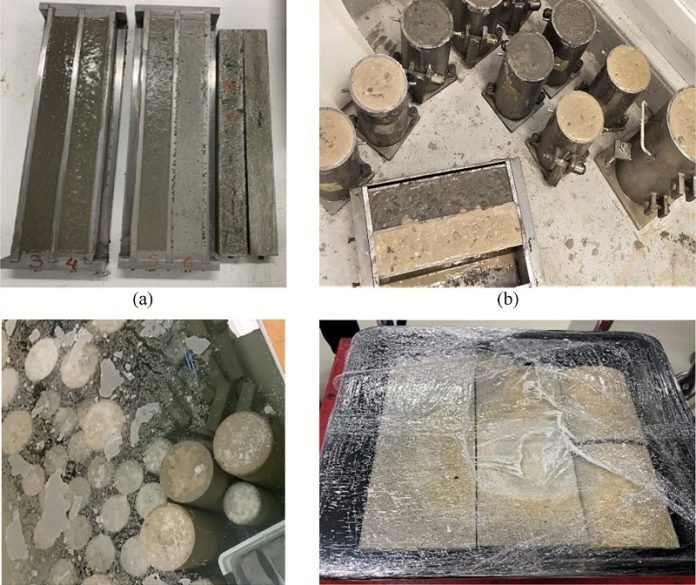

It’s made from recycled materials like old concrete and glass, turning what would be waste into a valuable resource for building.

One of the big hurdles in using recycled materials for concrete has been a problem called alkali-silica reaction (ASR).

This reaction can weaken the concrete over time because the silica in recycled glass reacts with the concrete’s basic components, causing it to expand and crack.

To tackle this, the team came up with a special mix that includes two key ingredients: ground granulated blast furnace slag (GGBS) and fly ash, a leftover from coal power plants.

Their studies showed that fly ash works better than GGBS at stopping the ASR reaction.

By adjusting the amounts of these two ingredients, they found the sweet spot where the concrete retains its strength and doesn’t absorb too much water, which are both important for durable construction.

Specifically, they discovered that combining 20% GGBS with 30% fly ash in the mix gives concrete similar strength and water resistance as traditional concrete made with natural sand.

This is great news because it means recycled glass and old concrete can be used without sacrificing quality.

However, adding more GGBS than that starts to weaken the concrete and make it soak up more water, which isn’t what you want.

The research, published in the Structural Concrete journal, highlights how the right balance of fly ash and GGBS can make recycled concrete a strong, sustainable choice for building projects.

Dr. Aliakbar Gholampour, who led the study, believes this new concrete mix could be a game-changer for the construction industry.

Not only does it offer a way to reuse materials that would otherwise end up in landfills, but it also cuts down on greenhouse gas emissions from cement production, helping the planet.

The research points out that fully replacing natural sand with glass sand in concrete does cause some issues, like making it more prone to ASR expansion and weakening its structure.

But, adding fly ash can significantly improve these problems, making the concrete much more durable and eco-friendly.

This breakthrough could mean a lot for our environment and our cities. It opens up possibilities for using recycled materials in roads, buildings, and infrastructure, reducing waste and saving natural resources.

With this new mix, the future of construction looks greener and more sustainable.