Researchers from UBC Okanagan, in partnership with Drexel University, have achieved a groundbreaking innovation in the world of telecommunications.

They’ve developed a new material that can be used to create 3D printed antennas and connectivity devices, potentially transforming how we build technology for communication.

This new compound, a mix of a two-dimensional material called MXenes and a polymer, could replace heavy metal parts in devices like antennas, waveguides, and filters, making them lighter, cheaper, and easier to produce.

Waveguides are crucial but often overlooked components in many electronic devices. They are essentially channels that guide sound and light waves through devices such as microwaves and satellite communication systems.

Traditionally, these components are made from metals due to their ability to conduct electricity well. However, metals can be heavy, expensive, and complicated to shape and assemble.

Enter MXenes, a new class of materials that are only a few atoms thick and known for their excellent electrical conductivity. Dr. Yury Gogotsi from Drexel University describes MXenes as “nanometer-thin conductive flakes,” likening them to clay that can be spread on almost any surface to make it conductive.

This process can be done at room temperature without needing to melt, evaporate, or apply metals under special conditions, making it incredibly versatile and accessible.

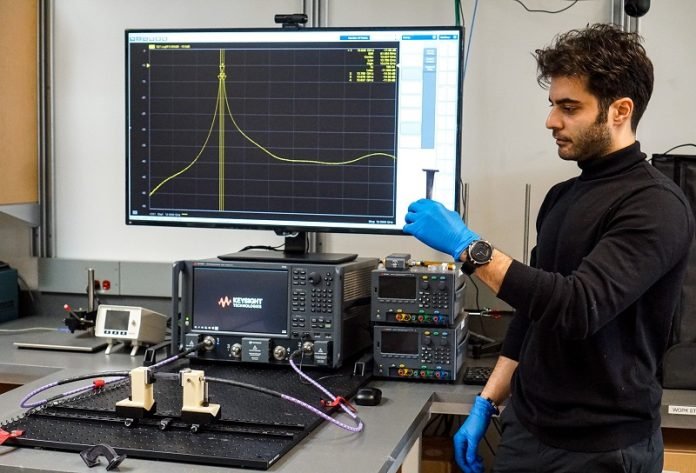

The team at UBC Okanagan’s Microelectronics and Gigahertz Applications (OMEGA) Lab, led by Dr. Mohammad Zarifi, has found that when MXenes are combined with a nylon-based polymer and 3D printed into parts, they can create waveguides and other communication components that are up to 20 times lighter and significantly cheaper than their metal counterparts.

This advancement could revolutionize the design and manufacturing of electronic communication devices, especially in sectors like aerospace and satellite communication, where weight and cost are critical factors.

The potential applications for this new compound are vast.

From improving the efficiency of space-based communication devices to enhancing medical imaging equipment like MRI machines, the lightweight MXene-coated polymeric structures could soon replace traditional metal parts in various high-tech applications.

This would not only reduce manufacturing costs but also lower the weight of devices, an essential factor in aerospace design where every gram counts.

With a provisional patent already filed for their polymer-based MXene-coated communication components, the researchers are optimistic about the future.

There’s still more work to be done to fully realize the potential of this innovative material, but the possibilities are exciting.

As Dr. Zarifi points out, this breakthrough could significantly reduce the payloads of shuttle transporters, offering engineers more flexibility and options for space exploration and beyond.

This development marks a significant step forward in telecommunications technology, opening up new avenues for the creation of lighter, more efficient, and cost-effective communication devices.

The future of communication could very well be shaped by the use of these advanced 3D printed materials.

The research is published in Materials Today.