In a pioneering effort that promises to reshape the landscape of future technologies, a research team from Kyushu University, alongside the Japanese company Nitto Denko, has made a significant breakthrough in the field of two-dimensional (2D) materials.

These materials, incredibly thin yet strong, hold the potential to revolutionize industries from electronics to medicine. However, until now, the challenge of incorporating these fragile materials into devices has been a major hurdle.

The team’s development of a special tape, as reported in Nature Electronics on February 9, 2024, offers a clever solution to this problem, simplifying the process of applying these materials to various surfaces.

2D materials are essentially materials that are only one atom thick, offering unique properties that are not found in their bulkier counterparts.

Among these materials, graphene stands out for its remarkable strength, flexibility, and conductive properties, making it a highly sought-after material for a range of applications, including sensitive sensors, flexible electronics, and advanced medical technologies.

Traditionally, transferring these ultra-thin materials onto devices has been a complex and delicate process, prone to tearing or contamination, which can degrade the material’s performance.

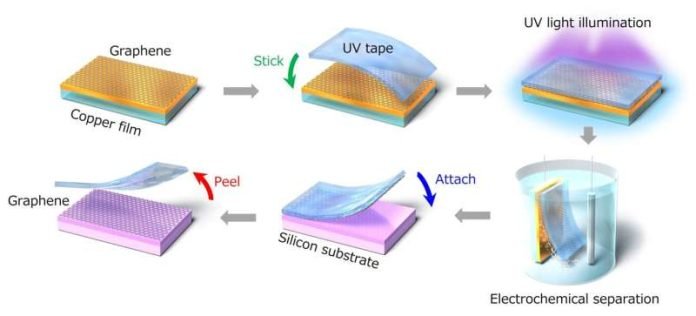

The conventional method involves growing graphene on a copper film through a process known as chemical vapor deposition.

The graphene then needs to be carefully separated from the copper and transferred to a suitable substrate, a process that is not only time-consuming and costly but also fraught with the risk of damaging the graphene.

The breakthrough tape developed by Professor Hiroki Ago and his team at Kyushu University’s Global Innovation Center, in collaboration with Nitto Denko, addresses these challenges head-on.

The tape, which utilizes ultraviolet (UV) light to adjust its stickiness, allows for the easy and precise transfer of graphene and other 2D materials to various substrates without the need for complex procedures or the risk of damage.

This UV tape is designed to strongly adhere to graphene initially. However, when exposed to UV light, the tape’s adhesion weakens, making it easy to peel away without leaving residues or causing defects.

This innovative approach not only streamlines the transfer process but also results in a smoother surface and fewer defects compared to traditional methods.

The potential applications of this technology are vast. For instance, the team has already demonstrated the use of graphene transferred via UV tape in creating a plastic device capable of sensing terahertz radiation.

Such sensors could revolutionize fields like medical imaging and airport security by providing safe, non-invasive alternatives to X-rays.

Looking ahead, the research team is focused on scaling up the size of the UV tape to meet manufacturing needs and overcoming challenges such as wrinkles and bubbles that can introduce defects during the transfer process.

Moreover, they are working on extending the stability of the 2D materials on the UV tape, allowing them to be shipped to and used by other researchers and developers with ease.

This development not only simplifies the handling and application of 2D materials but also opens up new avenues for their commercialization.

By making the transfer process as easy as using a sticker, the team at Kyushu University is paving the way for the wider adoption and exploration of 2D materials, potentially accelerating the pace of innovation and the development of next-generation technologies.

The research findings can be found in Nature Electronics.

Copyright © 2024 Knowridge Science Report. All rights reserved.