Imagine having a superhero suit that is both super strong and can stretch without tearing. That’s the kind of breakthrough scientists at the University of A and MIT have achieved, but not for superhero suits.

They’ve found a way to make materials that are both stiff (so they don’t bend easily) and tough (so they don’t break easily).

This discovery could change how things are made, from cars to buildings and even robots.

Published in the journal Science Advances, their research is like finding the perfect recipe for a material that can handle almost anything thrown at it.

Normally, materials can be made strong so they resist bending, or they can be made ductile (kind of stretchy), so they absorb energy and don’t break right away. But getting a material that does both well has been a big challenge.

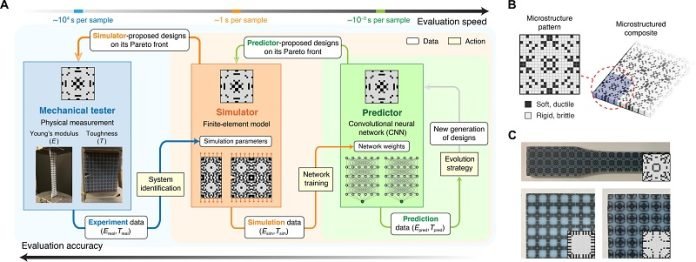

To tackle this, the team used a mix of real-life experiments, computer simulations, and something called machine learning (which is a smart way of letting computers learn from data to make predictions).

This combination helped them figure out how to design materials that have the best of both worlds: they’re strong and tough.

Here’s how they did it. They used a special printer (a 3D printer) to make tiny, complex materials that have these super properties. Then, they tested these materials in three ways:

A mechanical tester – This is like a mini gym for materials, where they are stretched and squished to see how they perform.

A computer simulator – This lets scientists do virtual tests, which saves time and materials.

A machine learning predictor – This is a computer program that learns from all the tests to make really quick guesses on how new designs might behave.

The mechanical tester is slow because making and testing each material takes time, but it gives very accurate results. The machine learning predictor is super fast but not as accurate. The simulator is in the middle, offering a good balance of speed and accuracy.

By using all three methods, the scientists found a way to quickly design materials that are just right in stiffness and toughness. This is a big deal because it can lead to materials that are safer, more durable, and more efficient for all kinds of uses, from everyday objects to advanced technology.

This research is exciting because it opens up new possibilities for making everything around us better, using the magic of 3D printing and smart computer programs. It’s like having a new superpower in the world of materials science.