In a groundbreaking development that could transform the safety of everything from sports gear to transportation, engineers from the University of Colorado Boulder and Sandia National Laboratories have introduced a revolutionary type of padding.

This new design, capable of withstanding significant impacts, might soon be integrated into football gear, bike helmets, and even the packaging used to protect delicate items during shipping.

Imagine padding that doesn’t just cushion a blow but actually works smarter by changing its form to absorb more force.

That’s exactly what this team has accomplished. Their research, detailed in the journal Advanced Materials Technologies, explores how we can go beyond traditional foam materials—which are great until they’re squished too much and become hard.

Foam is everywhere; it’s in the cushions we sit on, the helmets we wear, and the packaging that keeps our online orders safe. However, foam has its limits. Compress it enough, and it stops being soft and springy, turning into something much less helpful for absorbing shocks.

Enter the innovative minds at the University of Colorado Boulder and Sandia National Laboratories. They’ve taken a deep dive into the structure of padding materials, using computer algorithms to come up with a design that’s not just about the material itself, but how the material is arranged. The result? Padding that can absorb up to 25% more force than the best options currently on the market.

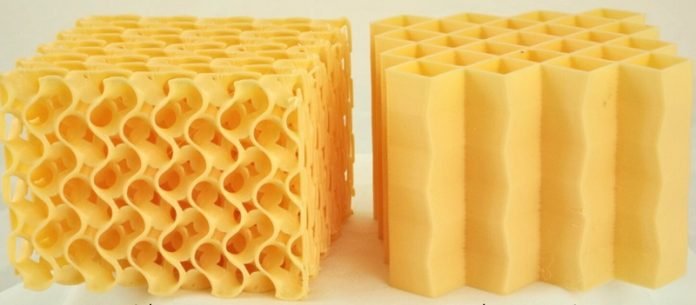

The secret lies in the geometry of the padding. Traditional padding works by squeezing together all those tiny spaces inside a foam, which soaks up energy. The next evolution in padding design was creating a lattice structure, like a honeycomb, which collapses in a controlled way under impact, making it more efficient at absorbing energy. But the team wanted something even more versatile, capable of handling various types of impacts with equal efficiency.

To achieve this, they started with a honeycomb design but then added special tweaks—little kinks that act like the bellows of an accordion. These kinks are designed to control how the honeycomb structure collapses under force, allowing it to smoothly absorb shock from impacts of all kinds, whether they’re fast and hard or slow and soft.

This isn’t just theoretical. The team has tested their designs in the lab, squashing their innovative padding under powerful machines to prove it works. What’s more, this high-tech cushioning can be produced with commercially available 3D printers, making it accessible for a wide range of applications.

The implications are vast. For athletes, this means potentially safer gear that could reduce the risk of injury from collisions and falls. For everyday people, it means bike helmets that offer better protection in accidents. And in the broader world, this technology could improve everything from the safety barriers on highways to the way we package fragile goods for shipping.

In essence, this research is not just about creating better padding; it’s about rethinking how we protect ourselves and the things we care about from the inevitable bumps and knocks of life, making the world a safer place one impact at a time.