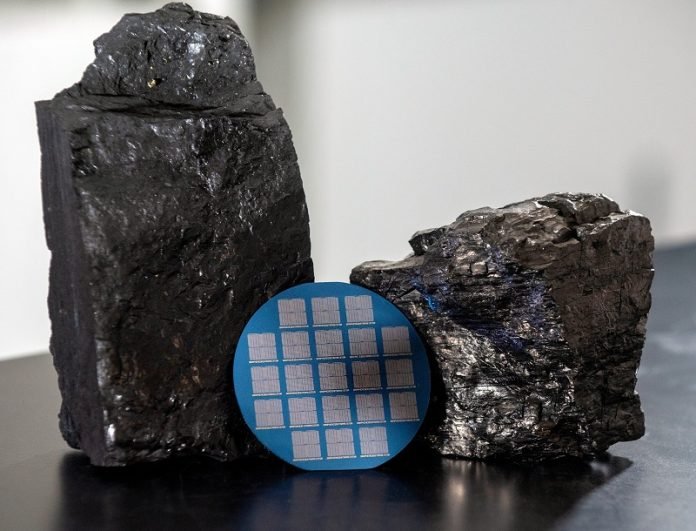

Coal has long been seen as a dirty source of energy, contributing to climate change.

But now, a team of researchers from the University of Illinois Urbana-Champaign, the National Energy Technology Laboratory, Oak Ridge National Laboratory, and the Taiwan Semiconductor Manufacturing Company are changing the story.

They’ve discovered an innovative use for coal in creating advanced electronic devices.

Professor Qing Cao, a materials science expert at the University of Illinois, explains that coal, often associated with bulkiness and pollution, can be processed into extremely thin, high-quality materials.

These materials are perfect for making tiny electronics that work better than current technologies.

The National Energy Technology Laboratory has developed a process that turns coal into tiny carbon dots.

These dots can then be connected to form thin membranes, useful for building 2D transistors and memristors. These are key components in the next generation of electronics, as reported in the journal Communications Engineering.

In the pursuit of smaller and faster electronics, the ultimate goal is to create devices only one or two atoms thick.

Such small devices work quickly and use less energy. While thin semiconductors are well-studied, thin insulators – materials that block electricity – are also needed to make effective electronic devices.

The team found that atomically thin layers of disordered carbon (made from coal) are great insulators for 2D electronics.

To show how well these work, Professor Cao’s group at the University of Illinois made two types of 2D devices.

Professor Cao finds it exciting that coal, typically seen as low-tech, is now linked to advanced microelectronics.

His team used carbon layers derived from coal as a gate dielectric in 2D transistors. This component is built on graphene or molybdenum disulfide. The result was devices that operate over two times faster and consume less energy.

These coal-derived carbon layers don’t have “dangling bonds,” which are unlinked electrons that can slow down the speed of a transistor.

Plus, unlike other thin materials, these carbon layers don’t have a regular crystalline structure. This means they don’t have leaky boundaries where unwanted electrical currents could flow, leading to more efficient devices.

Another application considered by the team is in memristors. These are electronic parts that store and process data, greatly enhancing AI technology.

The researchers found that using ultra-thin coal-derived carbon layers as insulators helps quickly form a conductive filament with low energy use.

This boosts device speed and power efficiency. The unique structure of the coal carbon also confines the filament, improving data storage fidelity and reliability.

The next step is to scale up these coal-based carbon insulators for industrial production. The semiconductor industry, including Taiwan Semiconductor, is keen on the potential of 2D devices.

Over the coming years, the University of Illinois will continue working with the National Energy Technology Laboratory to develop a production process for these coal-derived materials, paving the way for a surprising and eco-friendly use of coal in advanced technology.