In a thrilling development from The University of Queensland (UQ), researchers are pushing the boundaries of robotics with a new kind of 4D printing technology.

This isn’t just any ordinary printing – it’s about creating materials that can change shape and perform tasks, all thanks to some smart liquid metals and the power of lasers.

Let’s break it down:

What is 4D Printing?

4D printing is like 3D printing’s cooler cousin. With 3D printing, you can create solid objects from a digital model. 4D printing takes this a step further. Here, the objects printed can change their shape over time when exposed to certain triggers like heat, light, or water.

At UQ’s Australian Institute for Bioengineering and Nanotechnology, the focus is on using new liquid metal polymers that respond to infrared lasers. This means they can create structures that move and change shape on command.

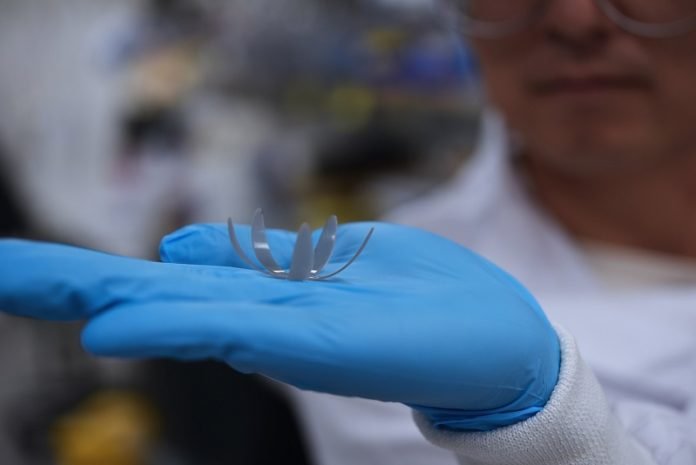

The lead researchers, Dr. Liwen Zhang and Dr. Ruirui Qiao, have developed unique ways to make these 4D designs. Their creations are not just solid and durable; they can perform actions like bending, grasping, lifting, and releasing items five times their weight or even return to a shape they were programmed to take.

Imagine a material that’s smart enough to change its shape just with a bit of laser light. That’s what these researchers have achieved.

The liquid metal polymers they’ve developed don’t need wires or circuits to change shape. They can be custom-made, molded, and then prompted to transform over time.

This technology is still in the early stages, but the possibilities are vast. Dr. Qiao envisions it being used in soft robotics. These are robots that mimic natural movements and interactions, perfect for delicate tasks in areas like aeronautical engineering and medical devices.

Imagine coronary stents that can adapt their shape inside the body, artificial muscles, or even other devices that need to change form once inside the body.

The team’s research isn’t just about robots. They see a future where this technology could lead to climate-responsive clothes, innovative building materials, and even self-assembling furniture.

The secret sauce of this technology lies in spherical liquid metal nanoparticles. These are used to prepare the printing resins that respond to near-infrared light. This responsiveness allows the material to bend and move when guided by lasers.

4D printing is a field that’s growing rapidly, and it’s really limited only by imagination. The materials created at UQ are unique because they respond to lasers. However, other 4D materials can react to different stimuli like water, heat, or even magnetic energy.

The research team at UQ is excited about the early results and the broad range of applications this technology could have.

In summary, what’s happening at The University of Queensland is nothing short of revolutionary. It’s not just about printing objects anymore; it’s about creating materials that can move, adapt, and transform – opening up a whole new world of possibilities in robotics and beyond.

This is 4D printing, and it’s just the beginning of a new era in manufacturing and technology.