Imagine turning on your lights or driving an electric car with more efficiency than ever before.

That’s the promise of a new discovery involving a tiny amount of a common carbon compound mixed with copper – the material commonly used for electrical wires.

This breakthrough, reported in the journal Materials & Design, challenges what we thought we knew about electricity and metals.

The brains behind this innovation are materials scientist Keerti Kappagantula and her team at the Department of Energy’s Pacific Northwest National Laboratory.

They found that graphene – a super-thin layer of carbon, like what’s in pencil lead – can significantly improve copper’s electrical properties.

This exciting find could lead to better electricity delivery in homes and businesses and make electric vehicle motors and industrial equipment more efficient. The team is even seeking a patent for this work.

So, what’s the big deal about graphene and copper? Well, it’s all about a metal’s temperature coefficient of resistance. This mouthful of a term simply means that metal wires heat up when electricity passes through them. The goal is to lower this resistance and boost how well a metal conducts electricity. For years, scientists have wondered if adding other materials to metals could improve their conductivity, especially at higher temperatures.

The PNNL team used a patented manufacturing method called ShAPE to mix just 18 parts per million of graphene with electrical-grade copper. The result? The copper’s resistance to temperature increased by 11% without harming its room-temperature electrical conductivity. In practical terms, for things like electric vehicle motors, this could mean a 1% increase in efficiency – a big deal in the world of electronics.

Kappagantula explains that this discovery turns our usual understanding of metals on its head. Normally, adding something to a metal makes it heat up faster at the same current levels. But with this new copper-graphene mix, they’ve achieved the opposite – enhanced conductivity.

The secret lies in the microstructure. The team’s detailed studies showed that the way they process the composite wire creates a uniform structure with tiny flakes and clusters of graphene. These are key to reducing the resistance of the composite.

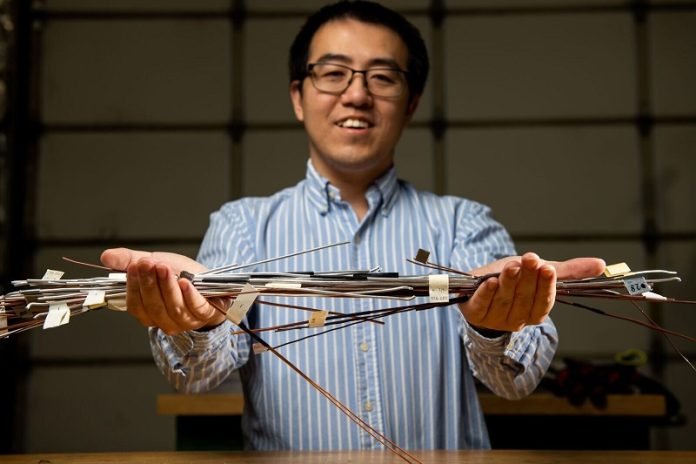

The team’s co-authors – Bharat Gwalani, Xiao Li, and Aditya Nittala – used a precision tool designed at PNNL to measure the improved conductivity. Li and Md. Reza-E-Rabby developed the process for creating this groundbreaking composite wire.

This copper-graphene combo isn’t just a lab curiosity. It has real-world implications, especially in electric motors and urban electrical wiring. Motors could run hotter without losing conductivity, and more conductive wires could help meet growing power demands in densely populated cities.

Kappagantula sums it up: “Anywhere there’s electricity, we have a use case.” The team is now focusing on refining the copper-graphene material and testing other important properties like strength, resistance to wear, and corrosion. They’re making wires as thick as a US penny to further these experiments.

This development isn’t just a step forward in materials science. It’s a leap towards a future where our everyday electrical devices – from home appliances to electric cars – work more efficiently than we ever thought possible.

Source: Pacific Northwest National Laboratory.