An engineering team from the University of Hong Kong, led by Professor Mingxin Huang, has achieved a groundbreaking development in the field of materials science.

They’ve created a new kind of stainless steel specifically designed for producing hydrogen, known as SS-H2.

This discovery is part of Professor Huang’s ambitious ‘Super Steel’ Project, which has already made significant strides in the past, like developing anti-COVID-19 stainless steel in 2021 and ultra-strong, ultra-tough steel in 2017 and 2020.

What Makes SS-H2 Special?

The team’s newly developed steel is resistant to corrosion, making it ideal for generating green hydrogen from seawater.

This is a major leap forward because it offers a sustainable and more affordable solution compared to current methods.

Typically, producing hydrogen from seawater involves using expensive materials like Titanium, but this new steel can do the job just as well and at a much lower cost.

The Science Behind the Steel

Stainless steel, a material known for its resistance to rust and corrosion, has been around for a century.

Its durability largely comes from Chromium, which forms a protective layer on the steel. However, traditional stainless steel has its limits, especially in very corrosive environments like seawater.

The HKU team’s SS-H2 steel uses a unique approach called “sequential dual-passivation.” This means that it has not just one, but two layers of protection against corrosion. The first layer, like in traditional stainless steel, is based on Chromium.

The second layer is made of Manganese, a surprising addition because Manganese was previously thought to weaken corrosion resistance. This double layer allows SS-H2 to withstand extremely corrosive environments, like those needed for water electrolysis in hydrogen production.

The journey to this discovery was not short. It took nearly six years of dedicated research, from the initial idea to the final product ready for industrial use.

This involved moving beyond the current understanding of corrosion resistance and developing new materials that can withstand higher potentials.

Currently, producing hydrogen from seawater or acid solutions is expensive. It requires components coated with precious metals like gold or platinum.

But with SS-H2, the cost of these components can be reduced dramatically.

For example, in a 10-megawatt electrolysis tank system, the cost of structural components can make up over half of the total expense. By using SS-H2 instead, these costs could be slashed significantly, by about 40 times.

The Road Ahead

The transition from lab to industry isn’t always easy. However, the team is making strides toward industrializing their discovery.

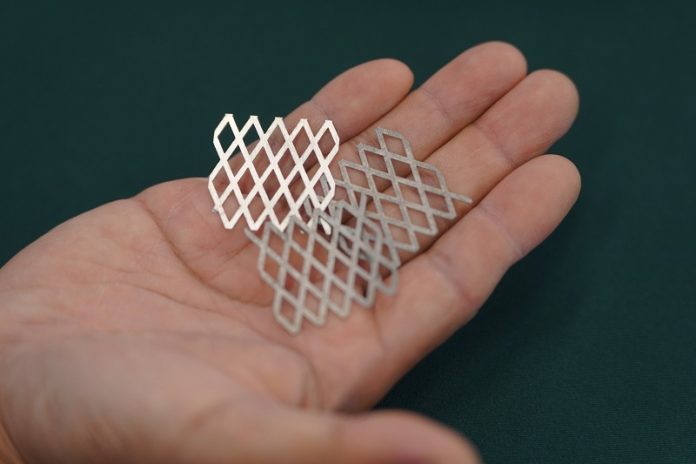

They have already started producing SS-H2-based materials like wires and meshes in collaboration with a factory.

The goal is to use this more economical and efficient material in large-scale hydrogen production, particularly from renewable sources.

This development is not just a scientific achievement; it’s a step towards more sustainable and affordable green energy solutions. The ultra stainless steel for hydrogen production could pave the way for more widespread use of hydrogen as a clean energy source, contributing to a greener future.