Have you ever thought about how we get the materials to make things like airplane parts or medical implants?

Scientists spend a lot of time in labs trying to find the perfect combination of materials to make these items better and safer.

But the University of Toronto team has a new trick up their sleeves – they’re using computers to speed things up!

Making materials is a bit like cooking. You mix different ingredients to get the desired end product.

And in materials science, this “cooking” is all about designing tiny patterns in the materials called “microstructures.” The way these patterns are arranged can determine how strong or flexible a material is.

But here’s the catch: finding the right pattern can take a very long time. Sometimes, it can even take years or decades. That’s because scientists have to run a lot of tests or simulations to figure it out.

Yu Zou, a professor at the University of Toronto, and his team are changing the game. They’re using machine learning – a type of computer system that can learn and make predictions – to help speed up this process.

Their recent study talks about a new way they developed to quickly find the best pattern for a popular metal called Ti-6Al-4V. This metal is a big deal because it’s used a lot in airplanes and medical stuff.

Xiao Shang, a student working with Professor Zou, says that their new method lets scientists find these patterns super-fast. All they have to do is tell the computer what kind of features they want in their material, and the system does the rest!

Think of their method as a two-step dance. First, they trained their computer to predict how different patterns would affect the material’s strength or flexibility. Then, they used a smart search method to find the best pattern that fits the desired outcome.

The results? Amazing! In just eight hours, they found a pattern for the titanium metal that made it perfect for airplane parts. And they even found another pattern that made the metal just right for medical implants, like the ones doctors put in our bodies when we break a bone.

But, of course, this wasn’t easy. The team had to teach the computer using a ton of examples, almost 6,000 different patterns! They did this with the help of powerful super-computers from the Digital Research Alliance of Canada.

Xiao Shang admits that they faced many challenges. Sometimes, their computer models didn’t work as they hoped. But they kept trying and searching for new ways to make things better.

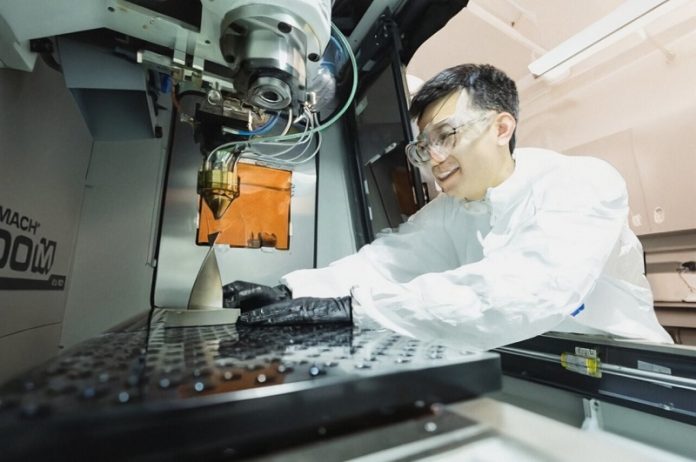

The next goal? They want to make 3D printing, a way of creating objects by adding layer upon layer of material, even better.

Two students working with Zou, Tianyi Lyu and Jiahui Zhang, are focusing on this. They’re trying to improve how metals are 3D printed so that their new method can be used more effectively.

Professor Zou has big dreams for the future. He envisions a world where doctors can 3D print medical implants that perfectly fit a patient’s needs in just a few days. Imagine going to a hospital, and instead of waiting weeks for an implant, you get one custom-made for you in no time!

The researchers at the University of Toronto are combining smart computers with materials science to make our world better.

From more efficient airplanes to personalized medical implants, the future looks bright – and it’s arriving faster than we thought!

Follow us on Twitter for more articles about this topic.

Source: University of Toronto.