In the dynamic world of wearable technologies, imagine a future where your health-monitoring devices can stretch, bend, and even self-repair, just like a superpower!

This isn’t a storyline from a science fiction movie, but a reality brought to us by dedicated scientists from the National University of Singapore (NUS).

They have created an extraordinary material that could transform not just wearable devices, but also robotics and an array of smart gadgets.

Wearable technology plays a pivotal role in our daily lives.

From fitness trackers that monitor our activity levels, to medical patches that keep an eye on our health, these devices are becoming indispensable.

Yet, one significant hurdle has always limited their capability: the electronic circuits within them, made from metals, are typically either too stiff or can be easily damaged.

This is where the magic of BiLiSC comes into play!

The Birth of BiLiSC: A Material with a Superpower

BiLiSC, short for Bilayer Liquid-Solid Conductor, is not your ordinary material.

Think of it as a superhero of materials, being able to stretch up to 22 times its original length without losing its ability to conduct electricity effectively.

So, how does this help? Well, consider a wearable patch that needs to adjust as our body moves – bending our elbow or knee, for example. BiLiSC ensures that such devices can stretch and bend harmoniously with our body while continuing to work without a hitch.

Professor Lim Chwee Teck, and his dedicated team at NUS, developed BiLiSC to meet the pressing need for durable, robust, and indeed, ‘unbreakable’ circuitry for the upcoming generations of wearable, robotic, and smart devices.

These applications are often subject to bends, stretches, and strains, requiring a material that can endure without losing functionality.

Two Layers, Double the Magic

BiLiSC works its magic with two distinctive layers. Imagine a sandwich cookie. The first layer (or the top cookie) is made of pure liquid metal, allowing it to be highly conductive, ensuring minimal loss of energy or signal even when stretched or bent significantly.

This means the electricity and data can flow efficiently even when the material is manipulated.

The second layer (the bottom cookie) is where the self-healing magic happens. This layer is a composite material, containing tiny microparticles of liquid metal.

When the material experiences a tear or crack, the liquid metal from these microparticles flows out and fills in the damaged area, healing it almost instantly while maintaining its high-level conductivity. So, if the wearable device experiences any damage, this layer ensures it repairs itself and keeps working seamlessly.

Practical Magic in the Real World

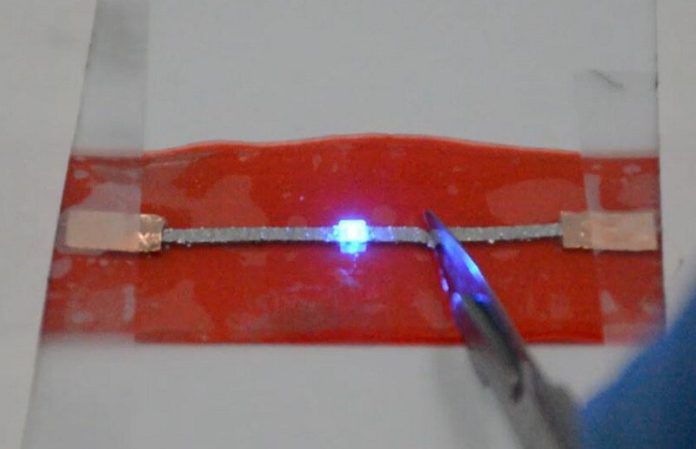

The team demonstrated that this spectacular BiLiSC material could be transformed into various electrical components vital to wearable technologies.

These include pressure sensors, wearable heaters, and even antennas for wireless communication.

In the testing phase, a robotic arm embedded with BiLiSC was not only swift in detecting and responding to pressure changes but also maintained consistent signal transmission despite being twisted and bent.

Not only does BiLiSC hold promise in its functionalities, but it’s also scalable and cost-effective in its manufacturing, ensuring that once it rolls out into the commercial market, it could be accessible and viable for varied applications.

The Future is Stretchable and Self-Healing!

Looking forward, the team at NUS is diving deeper into the world of material innovation and fabrication processes.

They are exploring ways to develop an enhanced version of BiLiSC that could be printed directly without the need for a template, reducing costs and improving precision in its creation.

In a nutshell, the development of BiLiSC paves the way toward a future where our wearable devices are not only more resilient and adaptive to our dynamic movements but also capable of healing themselves when damaged.

From healthcare to fitness, and from daily applications to specialized uses, this innovative material opens up a world of possibilities in creating devices that move, bend, and live just as we do.

This breakthrough doesn’t just signify an advancement in material science but propels us toward a future where technology adapts to us, in every stretch, bend, and twist of the way!

Follow us on Twitter for more articles about this topic.