Have you ever imagined fueling airplanes with the power of the sun? It sounds like something out of a sci-fi movie, right?

But, scientists at ETH Zurich are turning this dream into a reality!

They’ve made a huge leap forward in producing environment-friendly jet fuel using sunlight. Let’s dive in and see what this is all about.

A couple of years ago, these smart folks demonstrated a technology that uses sunlight and air to make liquid fuels. This was done right on top of their lab’s roof in Zurich! The best part? These sun-made fuels are super green.

When they burn, they release the same amount of CO2 that was used to make them, making them carbon neutral. This is great for our planet! Two companies, Climeworks and Synhelion, spun out of this project and are now trying to make this technology available to everyone.

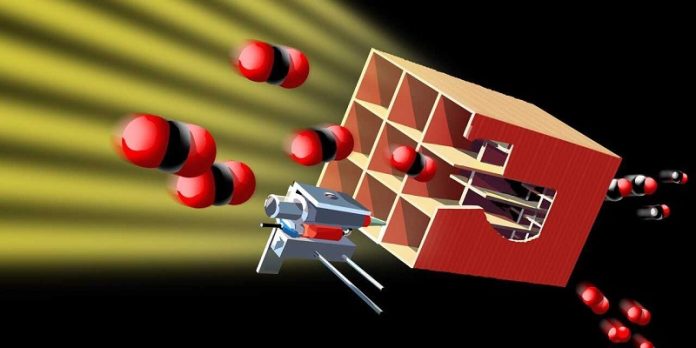

The magic happens in a special sun-powered oven called a solar reactor. Imagine a huge mirror focusing sunlight into this reactor.

It gets super hot – up to 1,500°C! Inside, there’s a special material called cerium oxide that heats up and helps split water and CO2 from the air. The result? A gas called syngas, which can be turned into jet fuel. Cool, right?

But there was a hiccup. The inside of the reactor didn’t heat up evenly. The sunlight would get weaker as it traveled deeper into the reactor, making the inner parts cooler and reducing the amount of fuel produced.

The 3D-Printed Game Changer Here’s where the breakthrough comes in. Researchers, led by professors André Studart and Aldo Steinfeld, figured out a new way to design the inside of the reactor using 3D printing.

They made special porous ceramic structures (think of them as spongy bricks) with tiny tunnels and channels that help sunlight travel deeper inside, heating everything up evenly. This means more of the special cerium oxide material gets to the reaction temperature of 1,500°C, and more jet fuel is produced.

The new design is like a sponge that has big holes on the outside and smaller ones as you go deeper. It’s built to absorb as much sunlight as possible. To make these spongy bricks, the team developed a unique 3D printing ink with the right characteristics.

Early tests show that these new 3D-printed reactors produce double the amount of fuel compared to the older designs! That’s a big win!

The good news keeps coming. The method used to 3D print these reactors is already patented. Synhelion, one of the spin-off companies we mentioned earlier, has gotten the license to use this technology.

They believe that this new reactor design can make sun-powered jet fuel more efficient and cheaper, which means a brighter, greener future for our skies!

In simple words, thanks to these brilliant scientists and their 3D-printed invention, we might soon see planes flying high using the power of the sun!

Follow us on Twitter for more articles about this topic.

Source: ETH Zurich.