In a breakthrough that could reshape modern electronics, researchers have developed a new method for making ultra-thin films.

Led by the Leibniz Institute of Photonic Technology (Leibniz IPHT) in Jena, Germany, this technique promises to create films tailored to specific needs, which could enhance the performance of gadgets we use daily, like solar cells and sensors.

So, what’s the big deal?

Thin films are like the building blocks of many electronics. Imagine a super-thin slice of a material, almost like a see-through slice of cheese, but way thinner!

These films are crucial for several gadgets and devices around us. However, making them with specific properties and without defects is tricky.

This research might have cracked that puzzle!

How do they do it?

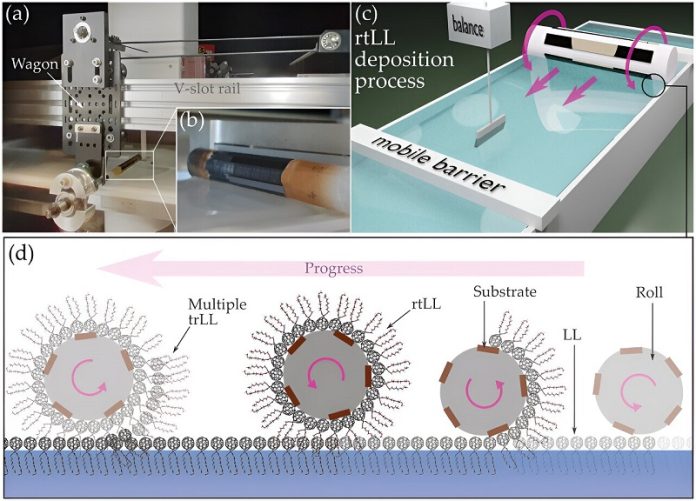

These researchers have come up with a technique called the “rolling transferred Langmuir layer” method.

In simpler terms, they’ve developed a rolling system that picks up a layer of molecules from the surface of water and deposits it onto a solid material. Think of it like using a rolling pin to pick up a delicate layer of dough and place it on a baking tray.

Previously, when using older methods, these films often ended up with cracks or defects, like a badly rolled-out pizza dough with holes in it.

But this new method ensures the films are smooth, uniform, and of high quality. It’s also scalable, which means it can be used to make large quantities, perfect for mass-producing electronics!

Customization is the key!

A great advantage of this new technique is customization. By tweaking the pressure during the rolling process, they can control how tightly the molecules in these films are packed together.

Moreover, they can decide on the exact number of layers they want, adjusting the thinness or thickness of these films. This is like choosing the thickness of your pizza crust, thin, regular, or deep-dish!

Why is this important?

The interactions between molecules and their arrangement in these films influence their energy levels.

These energy levels determine how efficient the films are in their jobs, like converting sunlight to electricity in solar cells.

By customizing these films, we can have more efficient gadgets, longer-lasting batteries, and more.

What’s next?

The researchers believe that their method will pave the way for next-generation electronic components with even better properties.

This could lead to solar panels that can convert more sunlight into electricity or new thin films that can turn sunlight into chemical energy. The possibilities are vast!

We’re on the brink of a revolution in electronics, thanks to a new technique that makes tailor-made thin films.

Developed by a team from Leibniz IPHT, this rolling method ensures high-quality films suited for various applications. With this advancement, we can look forward to even better electronics in the near future!

Follow us on Twitter for more articles about this topic.