In a significant breakthrough, researchers at Nottingham Trent University (NTU) have developed an innovative form of concrete, transforming waste sand from the metal casting industry into a sustainable construction material.

This eco-friendly approach could potentially save up to 100 million tons of waste foundry sand from being dumped in landfills worldwide, presenting an exciting green alternative for the construction industry.

Waste foundry sand is a byproduct of metal casting, used to create molds for shaping melted metals.

After several uses, this sand loses its utility for casting and typically ends up as waste, often disposed of in landfills, which raises environmental concerns.

The groundbreaking study led by Professor Amin Al-Habaibeh, a specialist in intelligent engineering systems, explored the possibility of repurposing waste foundry sand to create a new type of concrete suitable for lighter loads.

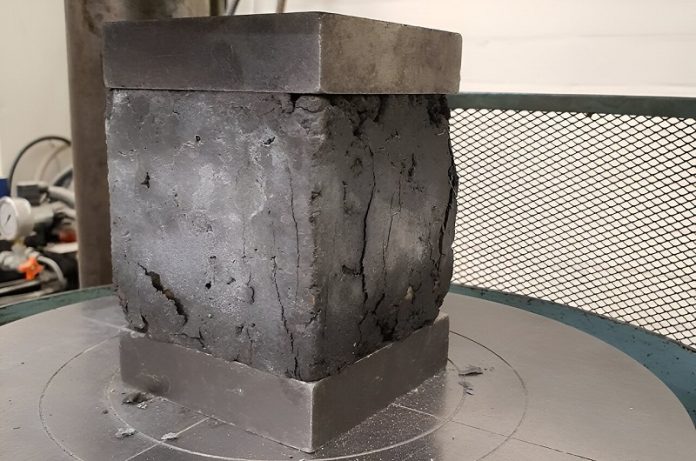

The results of the research, published in Energy and Sustainable Futures: Proceedings of the 3rd ICESF, 2022, revealed that concrete containing up to 30% of recycled waste foundry sand maintains up to 78% of the compression strength of traditional concrete.

This level of strength makes it a viable material for manufacturing various concrete products such as garden slabs, curb stones, and cycling pavements, which do not have to bear heavy weights.

This innovative concrete can be a reliable substitute for many concrete applications where maximum strength is not a critical requirement.

Integrating waste foundry sand in the production of concrete is beneficial both environmentally and economically.

It helps in reducing the dependency on natural sand, subsequently decreasing the amount of waste foundry sand directed to landfills. Additionally, the incorporation of waste foundry sand can reduce the overall production costs of concrete and decrease CO2 emissions during the transportation of materials.

The newly developed concrete with waste foundry sand has a compression strength of about 23 newtons per square millimeter (N/mm2). Even though the recycled sand might result in a minor drop in the technical performance of the end products in some areas, it’s an acceptable compromise for a wide range of concrete products, based on the required applications. It can efficiently replace standard sand, partially or wholly, in quality mortars and concretes designed for lighter loads.

Professor Al-Habaibeh remarked optimistically about the innovative approach, saying, “This is good news for the environment, as it shows that the use of natural sand can be reduced, and therefore so can the need for sending waste foundry sand to landfill.”

This development marks a considerable step forward in sustainable construction methods and environmental protection. It highlights the crucial role of recycling and efficient resource utilization in paving the way for a more sustainable and eco-conscious future.

By turning waste into a valuable resource, we are not only optimizing construction practices but also contributing to environmental conservation and resource efficiency.

The novel research by NTU provides a practical, sustainable, and cost-effective solution, emphasizing the transformative power of intelligent engineering in building a greener planet.

Follow us on Twitter for more articles about this topic.

Source: Nottingham Trent University.