In a significant breakthrough, scientists at Rice University have devised an ingenious method to recycle batteries, potentially transforming the way we reclaim valuable metals from used batteries.

This innovative approach, involving a ‘flash’ Joule-heating technique, aims to make the recycling process more efficient, eco-friendly, and economical.

The problem today is that most of our devices, like phones, laptops, and electric vehicles, use batteries containing precious metals such as cobalt and nickel.

Although these metals can be reused, extracting them from spent batteries has traditionally been cumbersome, expensive, and involved the use of strong, environmentally harmful acids.

With the escalating demand for these metals due to the rise in electric vehicles and renewable energy technologies, finding efficient recycling methods has become imperative.

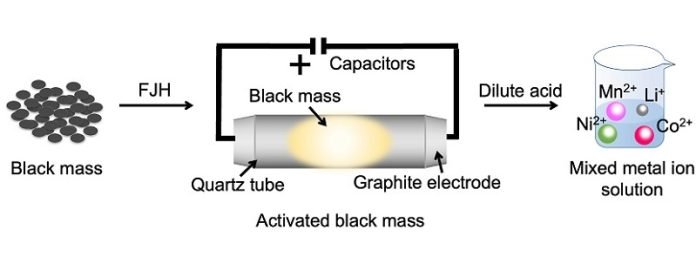

James Tour, a chemist from Rice University, led the team in developing this innovative technique, where they quickly heated the combined waste from the battery’s cathode and anode, known as “black mass,” to temperatures above 2,100 degrees Kelvin.

This method altered the metals’ state, allowing them to dissolve in low-concentration acid, enabling the extraction of over 98% of metals from mixed battery waste in a more sustainable manner.

This breakthrough matters profoundly because it significantly cuts down the time and environmental impact associated with the battery recycling process.

The metals can now dissolve in less than 20 minutes, a drastic reduction from the conventional 24 hours. Additionally, this method reduces secondary waste streams and lowers carbon dioxide emissions, presenting a more environmentally conscious alternative to existing solutions.

Furthermore, it offers an economical advantage by reducing the costs associated with battery waste recycling through decreased consumption of energy, water, and acid. This economical solution is vital as, currently, only 5% of batteries are recycled due to inadequate capacity and increasing electronic waste at a rate of 9% annually.

This novel approach is not just a leap in battery recycling; it also opens up the possibility of sourcing metals more efficiently since metals in many lithium-ion batteries are often found in higher concentrations than in natural ores.

Efficient battery recycling methods like this one can potentially make electric vehicles more affordable and competitive, reducing the overall costs associated with battery production and contributing to a more sustainable approach to metal consumption and waste management.

Moreover, the significance of advances in battery recycling research cannot be overstated, especially as we move towards more sustainable energy and transportation solutions.

With the market for battery recycling expected to experience considerable growth, innovations like the one developed at Rice University are likely to play a key role in shaping the energy and transport sectors, enabling a more sustainable and eco-friendly future.

In conclusion, the groundbreaking battery recycling process developed by Rice University is a monumental step towards a future where valuable metals can be reclaimed efficiently, economically, and eco-friendly.

It holds the potential to revolutionize the recycling industry and reduce the environmental impacts of battery usage and disposal.

This technique can significantly contribute to making the production of electric vehicles more cost-effective and environmentally sustainable, steering us towards a greener, more resource-efficient world.

Follow us on Twitter for more articles about this topic.