In a game-changing moment for the trillion-dollar global nanosensor industry, engineers at Macquarie University have found a way to make nanosensors faster, cheaper, and greener.

This remarkable discovery revolves around a tiny droplet of ethanol.

A Mistake that Sparked a Breakthrough

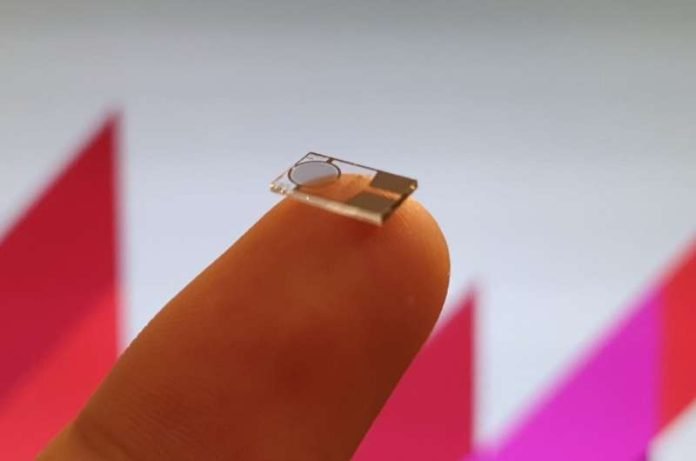

Nanosensors, tiny devices made of billions of nanoparticles, are notorious for being finicky. When these nanoparticles come together, they often leave gaps, rendering the sensor useless.

Usually, manufacturers need to heat them for a long 12-hour process to get the sensors working. However, this intense heating can ruin many sensors, limiting the types of materials that can be used.

This all changed when postgraduate student Jayden (Xiaohu) Chen had an accidental splash of ethanol on a sensor. Instead of the device being destroyed, the sensor performed better than any they had ever created.

This accidental discovery led the team to delve deeper into the potential of ethanol in nanosensor production.

A Single Drop Changes Everything

Ethanol, commonly found in alcoholic drinks and some fuels, seems to be the magic ingredient for nanosensors.

Associate Professor Noushin Nasiri, who led the research, explained that placing just one droplet of ethanol on the sensor layer allows the nanoparticles to move around and close the gaps between them.

The ethanol does in a moment what used to take hours of heating.

Finding the perfect amount of ethanol was crucial. “It was like Goldilocks,” Nasiri explains. “Three microlitres was too little, 10 microlitres was too much, but five microlitres was just right!”

A Future Defined by Efficiency

This ethanol method isn’t just faster; it also widens the possibilities. Sensors that previously couldn’t endure the intense heat can now be made without any heat at all.

This breakthrough can have massive implications for the variety of materials used in the industry.

Nasiri’s team has tried this technique on various nanosensors, from UV light sensors to ones that detect gases like carbon dioxide and methane.

The results were consistently impressive. “After one correctly measured droplet of ethanol, the sensor is activated in around a minute,” Nasiri notes.

In an industry that’s always searching for efficiency and innovation, this simple ethanol solution is set to make waves.

Not only does it promise to make sensor production less carbon-intensive, but it also paves the way for a broader range of more effective sensors in the future.

The study was published in Advanced Functional Materials.

Copyright © 2023 Knowridge Science Report. All rights reserved.