Imagine a future where your smartphone can be folded like a piece of paper, or where your television screen is as thin as a sheet of plastic.

Scientists at the Indian Institute of Science (IISc) have made a significant breakthrough in creating a new type of semiconductor material that could make these futuristic technologies a reality.

In their study published in Advanced Materials Technologies, researchers have developed a super flexible composite semiconductor that has the potential to revolutionize the display industry and open doors to exciting new possibilities in wearable electronics and foldable devices.

Semiconductors, like transistors, are the building blocks of electronic circuits that power our devices.

However, the semiconductor materials currently used in display industries, such as amorphous silicon and amorphous oxides, are not flexible and cannot withstand strain.

Although adding polymers to these materials can increase flexibility, there is a limit to how much can be added without compromising the semiconductor’s performance.

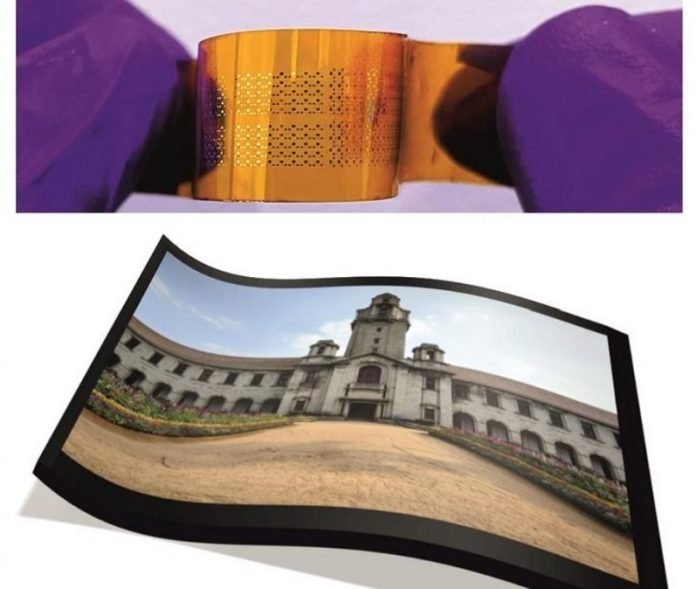

A Flexible Composite Semiconductor: In their research, scientists have discovered a way to create a composite semiconductor using a technique called inkjet printing.

Unlike previous studies that reported minimal polymer additions of only 1-2%, this new method allows for a significant amount of polymer, up to 40% of the material’s weight, to be added without affecting the semiconductor’s properties.

This large quantity of polymer makes the composite semiconductor highly flexible and foldable while maintaining its performance.

The composite semiconductor is composed of two materials: a flexible, water-insoluble polymer called ethyl cellulose and a semiconductor called indium oxide. By mixing the polymer with the oxide precursor, the researchers were able to create interconnected pathways within the material.

These pathways allow electrons to move from one end of a transistor to the other, ensuring a steady flow of current. The choice of the right kind of water-insoluble polymer was crucial in creating these pathways and making the material super flexible.

Instead of traditional deposition techniques, the research team used inkjet printing to deposit their material onto various flexible substrates like plastics and paper.

Similar to printing words and images on paper, electronic components can now be printed on any surface using functional inks containing conducting, semiconducting, or insulating materials.

However, challenges exist, such as obtaining a continuous and uniform film and ensuring the right printing conditions.

In the future, these printed semiconductors could be used to create fully printed and flexible television screens, wearables, and large electronic billboards. They could work alongside printed organic light-emitting diode (OLED) display front-ends.

These printed semiconductors will be cost-effective and easy to manufacture, potentially revolutionizing the display industry. The researchers have obtained a patent for their material and plan to test its quality control and shelf-life before scaling up for mass production.

Additionally, they will explore other polymers that can further enhance the design of flexible semiconductors.

With the development of super flexible composite semiconductors, we are one step closer to a future filled with foldable devices, curved displays, and wearable electronics.

The innovative inkjet printing technique allows for the creation of flexible electronic components on various surfaces, promising exciting advancements in the field of technology.

As scientists continue to refine and explore the possibilities of printed semiconductors, the world of electronics is poised for a remarkable transformation.

Follow us on Twitter for more articles about this topic.