Scientists from the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) have come up with an exciting idea to make some of the most efficient solar cells cheaper.

They’re using sound waves in a process they call ‘acoustic spalling’.

Their study, titled “GaAs solar cells grown on acoustically spalled substrates with 27% efficiency,” is published in the scientific journal Joule.

Let’s start by understanding what these efficient solar cells are. They’re called III-V solar cells. The name comes from the groups of elements from the periodic table that are used to grow these cells.

The problem with these cells, though, is that they’re really expensive to produce, which has limited their use mainly to power satellites in space.

One way to make these cells cheaper is to reuse the base material, or ‘substrate’, on which the cells are grown. Here’s where the cool new technique comes in.

Usually, the cell is lifted off the substrate using a layer that can be etched away. But this method leaves behind a residue, and the substrate then needs to be polished.

This process is not only time-consuming but also costly, eating into the cost savings gained from reusing the substrate.

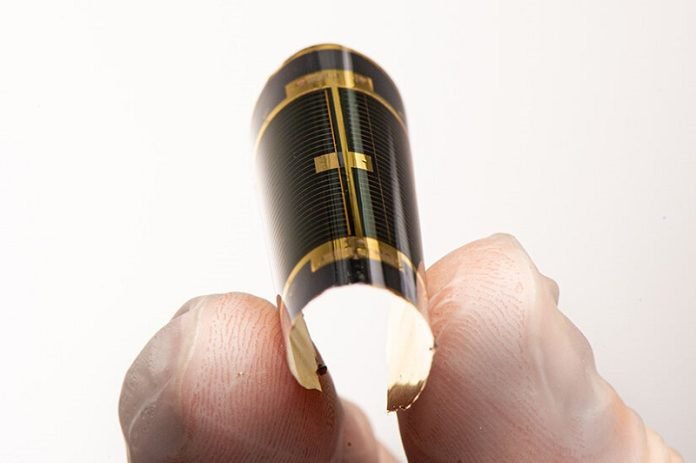

The NREL team found a faster and cheaper alternative. They apply sound waves to create a controlled break within the substrate, pretty much like splitting it parallel to its surface.

This method, known as spalling, lets the cell be removed easily, revealing a fresh surface that doesn’t need any expensive polishing.

Standard spalling tends to leave uneven surfaces on the substrate, which require extra material and might still need some form of polishing.

The NREL scientists’ approach of acoustic spalling uses sound waves to control the break and keeps the surface smoother.

Kevin Schulte, the lead author of the study, explains that the smoother surface lets them grow a new cell on it without having to do much (or any) prep work. It’s like having a clean, prepped canvas ready for the next masterpiece.

Acoustic spalling was initially developed at Arizona State University and is now being brought to the market by a Phoenix-based company, Crystal Sonic Inc.

Future research is needed to understand how many times a substrate can be reused using this Sonic Lift-Off technique, but initial results are promising.

The researchers successfully built a cell on a previously used substrate with an efficiency of 26.9%.

Schulte is optimistic about the results, saying, “I don’t think there’s any difference in that performance compared to what efficiency we could get on a brand-new substrate.”

This means we could have super-efficient solar cells at a much lower cost in the future – all thanks to the power of sound!

Follow us on Twitter for more articles about this topic.