Have you ever thought about how the tanks and armored vehicles used by the military are protected?

Most of these land-based military vehicles use a type of protective covering called Rolled Homogeneous Armor (RHA) or high hardness steel (HHS) armors.

These materials are generally cheaper than others, but are they the best option?

A group of scientists and engineers from companies and universities like Rheinmetall BAE Systems Land (RBSL), the University of Sheffield, BAE Systems, and more, are working on a project called the Affordable Titanium to Useable Defense Equipment (ATiTUDE).

They’re looking to make defense protection lighter, stronger, and more cost-effective by using titanium.

Why titanium, you ask? Titanium alloys, the blend of titanium with small amounts of other metals, are much more efficient than the traditional steel armors.

They can reduce the weight of the armor by about 30%–40% while still keeping our soldiers safe. Less weight means vehicles can move faster and use less fuel, which can be critical in defense situations.

The challenge, though, is that titanium is usually more expensive than steel. But, the ATiTUDE team is developing a new way to make titanium armor, using something called powder metallurgy.

This method involves using a powder form of titanium, even reusing waste materials like oversized titanium powder or scraps from machine cutting processes.

Once they’ve made the powder, they use high-tech equipment like the FCT HP D 250 (FAST/SPS) and the FENN Hot Rolling Mill, located at the University of Sheffield. This process helps to shape the titanium into armor plates.

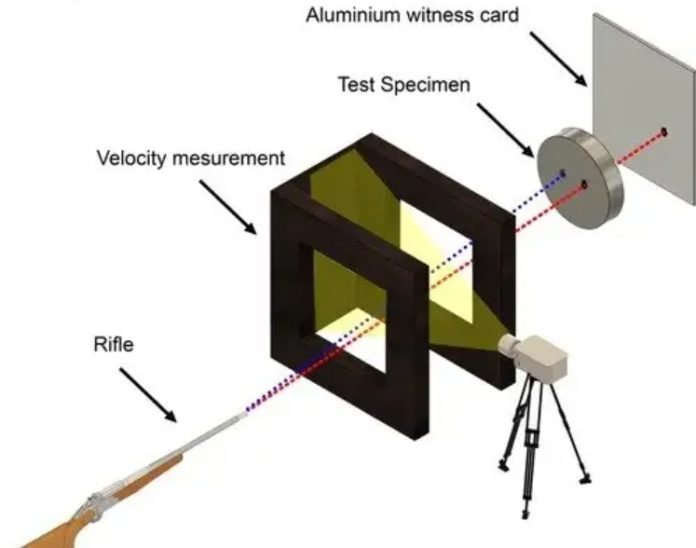

What’s even more exciting is that these new titanium armors have passed ballistic testing, meeting the tough standards set by the military. That means these armors can stand up to the threats our military vehicles might face.

This breakthrough presents a huge opportunity for creating affordable, efficient, and sustainable armor for the future, making our defense forces more agile and safer. The findings are shared in a scientific journal called Materials Science and Technology, showing just how impactful this work could be.

This project shows that innovation can come from even the most unexpected places. And who knows, the old scraps from your high school metalwork class might just be part of the next big breakthrough in defense technology!

The paper is published in the journal Materials Science and Technology.

Follow us on Twitter for more articles about this topic.