Robots are getting smarter and more useful every day.

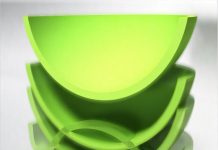

A group of scientists from the University of California San Diego, along with some helpers from a company called BASF, have come up with a cool new kind of robot hand.

It’s made using a special 3D printer, and the best part is that it doesn’t need any electronics to work!

Usually, when we think of robots, we imagine lots of wires and electronics.

But this new robot hand, also known as a ‘soft robotic gripper’, doesn’t need any of that. It’s ready to use as soon as it’s printed, which is really cool.

The scientists wanted to make a robot hand that could feel gravity and touch, like a real hand. That way, it can pick up, hold, and let go of things.

There’s never been a robot hand quite like this one before.

So, how does it work? Yichen Zhai, one of the scientists who worked on this, explained that they set up some valves in the hand.

These valves control air flow, so when the hand touches something, it can grip it.

Then, if you turn the hand sideways, the change in airflow makes the hand let go. It’s like the hand ‘remembers’ that it’s holding something until it feels the weight of the object shift, then it knows to let go.

This kind of technology is part of what’s called ‘soft robotics’. It’s all about making robots that are safe to be around people and can handle delicate things.

This new robot hand could be really useful for jobs like making things in factories, picking up food, and even exploring new places.

It can be attached to a robot arm or work on its own, powered by just a bottle of high-pressure gas.

Now, you might be thinking, don’t other 3D printed robots already exist? Yes, but they usually have some problems.

They’re often kind of stiff, they might have leaks, and they need a lot of work after they’re printed to make them usable.

The team of scientists came up with a new way to 3D print to get around these problems. They made the printer follow one continuous path for each layer it prints, kind of like drawing a picture without ever lifting your pencil.

This means there’s less chance of leaks and problems in the finished product, which is really good news when you’re working with soft materials.

This new method also lets the scientists print really thin walls, even as thin as half a millimeter! These thinner walls can bend and flex more, which makes the robot hand softer and more flexible. The scientists got the idea for this method from a type of maths called graph theory.

There’s a thing in graph theory called an Eulerian path, which is a path that goes over every line in a shape exactly once.

As Michael T. Tolley, one of the senior scientists on the project, said, “When we followed these rules, we were able to consistently print functional pneumatic soft robots with embedded control circuits.”

In simpler terms, they were able to print a soft robot hand that could control itself, all in one piece!

The study was published in Science Robotics.

Follow us on Twitter for more articles about this topic.

Source: UC San Diego.