Researchers at the University of Waterloo have made a groundbreaking discovery that could have a significant impact across various industries.

They have developed an innovative method called liquid-liquid encapsulation, which offers a simple and cost-effective way to protect and deliver important substances.

Let’s explore this exciting new technology!

Encapsulation is like placing something valuable inside a protective shield. Imagine a tiny drop of precious liquid or liquid containing special ingredients being carefully covered in a protective layer.

This process, developed by the brilliant minds at the University of Waterloo, can be incredibly useful in industries such as nutraceuticals, pharmaceuticals, food and beverages, cosmetics, and personal care.

So, how does this technology work? Well, it’s quite fascinating! The researchers use a liquid-liquid encapsulation system that involves introducing a drop of the core material through a nozzle.

This drop then lands in a special liquid bath, which has a floating layer on the surface. When the core material interacts with this layer, something amazing happens—it forms a stable protective shell around the core.

This shield keeps the core material safe from any harsh environment it may encounter and allows it to be released at the right time and in the right place.

One of the most incredible aspects of this technology is that everything happens in a liquid state. The core material, the protective shell, and even the bath they’re submerged in are all liquids.

This liquid flexibility allows for a wide range of combinations between different core materials and shells. In fact, the researchers have already demonstrated at least 15 different combinations!

Another fantastic feature of this method is its speed. Each encapsulation takes only a mind-bogglingly fast 50 milliseconds. That means thousands of encapsulations can be created in just an hour.

Not only is this process remarkably quick, but it’s also incredibly energy-efficient.

It uses around 5,000 times less energy compared to other methods. Plus, it doesn’t introduce any harmful microplastics into the encapsulation process, making it environmentally friendly.

This revolutionary technology has the potential to transform various industries. For instance, in the nutraceutical industry, where they create nutritional supplements, this liquid-liquid encapsulation can reduce operating costs and pave the way for the development and production of new products.

Multiple core materials can be encapsulated and delivered together in a single package, thanks to this method.

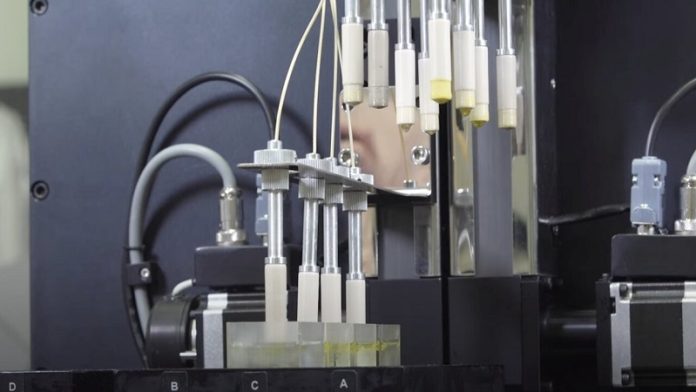

The researchers at the University of Waterloo are not stopping there. They have built a sturdy prototype with four injection nozzles that can produce up to a staggering 200,000 encapsulated units per hour.

Furthermore, they are collaborating with partners and product manufacturers in the Netherlands to enhance their prototype. They aim to integrate a stage where the encapsulated cargo can be extracted as individual capsules whenever needed.

Dr. Sushanta Mitra, the executive director of the Waterloo Institute for Nanotechnology and a professor of Mechanical & Mechatronics Engineering, envisions a future where encapsulation technologies are sustainable and align with the United Nations’ sustainable development goals. This incredible liquid-liquid encapsulation discovery brings us one step closer to that goal.

With this groundbreaking technology, scientists are opening up new possibilities for protecting and delivering valuable substances across industries.

Who knows what other exciting breakthroughs lie ahead? The world of encapsulation is evolving, and it’s an exciting time to witness innovation at its best!