Scientists at the University of British Columbia (UBC) have achieved a groundbreaking feat by transforming sticky bitumen, derived from Alberta’s oil sands, into remarkable carbon fibers.

Typically burned as fuel or repurposed for asphalt pavement, bitumen can now be converted into valuable carbon fibers.

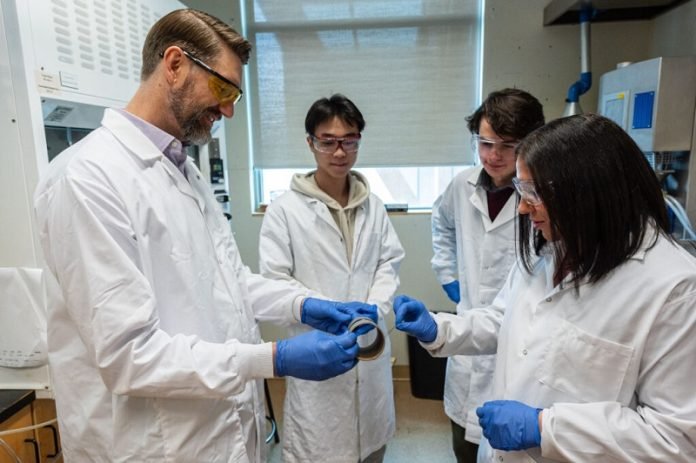

This innovation by UBC materials engineer Dr. Yasmine Abdin and her colleagues, Dr. Frank Ko and Dr. Scott Renneckar, promises cheaper and more accessible carbon fibers for use in various industries.

The team’s discovery, published in the journal Advances in Natural Sciences: Nanoscience and Nanotechnology, has won recognition and funding through the Carbon Fibre Grand Challenge, a competition focused on recovering valuable products from oil sands.

Carbon fibers, known for their lightweight and durable nature, are widely used in aerospace applications (like aircraft), sports equipment (such as hockey sticks), and electric vehicles (EVs).

These fibers make EVs safer, more efficient and help improve overall vehicle performance. Dr. Abdin emphasizes that incorporating carbon fibers into EV chassis can offset the weight of heavy battery packs, enhance battery cooling for increased safety, and extend the driving range.

As Canada aims to reduce emissions and boost the adoption of EVs, utilizing locally produced carbon fibers provides automakers with a competitive advantage while supporting national emission reduction goals.

The UBC research team has developed a cost-effective method, called melt spinning, to convert bitumen into high-quality carbon fibers.

Unlike traditional production processes, their innovative technique enables clean and economical fiber manufacturing. The projected cost for their carbon fibres is only $12 per kilogram, significantly lower than the typical price of $33 per kilogram for commercial carbon fibres.

This affordability opens up new opportunities for industries that require carbon fibres, making them more accessible and economically viable.

The breakthrough discovery by UBC researchers not only benefits the automotive sector but also has broad applications across different industries. Electric vehicle manufacturers can leverage these affordable carbon fibres to enhance their products and make EVs more appealing to consumers.

Additionally, the use of local carbon fibres supports Canadian automakers by providing them with a competitive edge in the global market. Furthermore, other industries that rely on carbon fibres, such as aerospace and sports equipment manufacturing, can benefit from the lower cost and increased availability of these advanced materials.

UBC researchers have unlocked the potential of bitumen, a byproduct of Alberta’s oil sands, by transforming it into valuable carbon fibres.

These fibers, renowned for their strength and lightweight properties, offer a range of benefits, from making electric cars safer and more efficient to improving performance in various industries.

With a cost-effective production process, the UBC team aims to commence commercial production of carbon fibres in 2024.

This innovative breakthrough has the potential to revolutionize the manufacturing landscape, benefiting Canada’s automotive sector and contributing to the nation’s emission reduction goals.