Scientists have made an exciting discovery in the field of fusion energy, bringing us one step closer to a cleaner and more sustainable future.

A team of researchers from various institutions, including Los Alamos National Laboratory, has developed a remarkable tungsten-based alloy capable of withstanding extreme conditions similar to those found in fusion reactors.

This breakthrough could revolutionize the way we harness fusion energy and make it more efficient and economically viable.

Fusion energy, which produces power by mimicking the sun’s energy generation process, requires materials that can endure the intense conditions within a fusion reactor.

These conditions include high temperatures, exposure to radiation, and extreme stress.

Unfortunately, existing materials, such as tungsten, degrade and deform under such circumstances. Solving the materials challenge is vital to making fusion power a practical and reliable energy source.

To address this challenge, the research team developed a nanocrystalline high entropy alloy.

This alloy consists of five or more elements and possesses a unique crystalline structure at the atomic level.

The team chose tungsten as the primary component of the alloy because it has been extensively studied for plasma-facing components in fusion reactors.

By employing calculations, simulations, and advanced computational methods, the researchers identified hafnium as an ideal element to include in the alloy mix.

Hafnium’s performance was predicted to be highly suitable for fusion conditions.

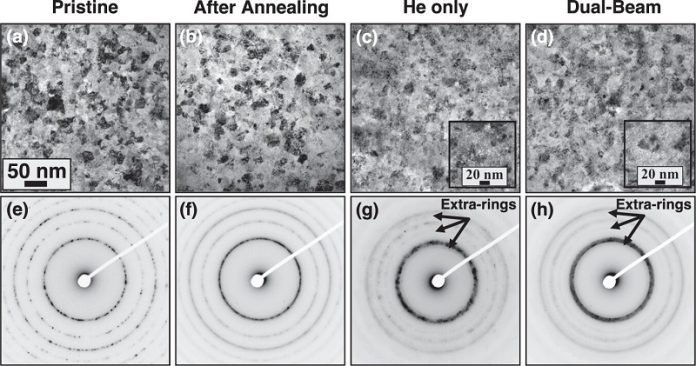

The team fabricated thin films of the alloy and subjected them to rigorous testing in experimental conditions simulating a fusion reactor.

One set of samples was irradiated at Argonne National Laboratory, while another was irradiated at the Ion Beam Materials Laboratory at Los Alamos. The alloy demonstrated exceptional resistance to irradiation and retained its structural integrity throughout the experiments.

Moreover, the team also explored the synthesis of amorphous alloys, where atoms do not align in a regular pattern as in crystalline structures.

By incorporating hafnium into amorphous alloys, they discovered enhanced stability under irradiation and heat treatment, which are crucial aspects of fusion settings.

Although further research and experimentation are required, these early breakthroughs pave the way for the development of new alloys suitable for fusion reactors.

The success of this work enables scientists to use high-throughput simulations and experiments to design and assess future materials.

Ultimately, these advancements will contribute to the selection of materials that can advance fusion energy technology to a higher level of readiness.

The recent development of a tungsten-based alloy capable of withstanding extreme conditions brings us one step closer to harnessing the immense power of fusion energy.

This breakthrough offers hope for a cleaner, more sustainable future by addressing the materials challenges associated with fusion reactors.

With continued research and advancements in materials science, fusion power generation may soon become a practical and economically viable solution for our energy needs.

Their results were published in Nature Communications, and Applied Materials Today.