Microwaves are useful for more than just heating up leftovers.

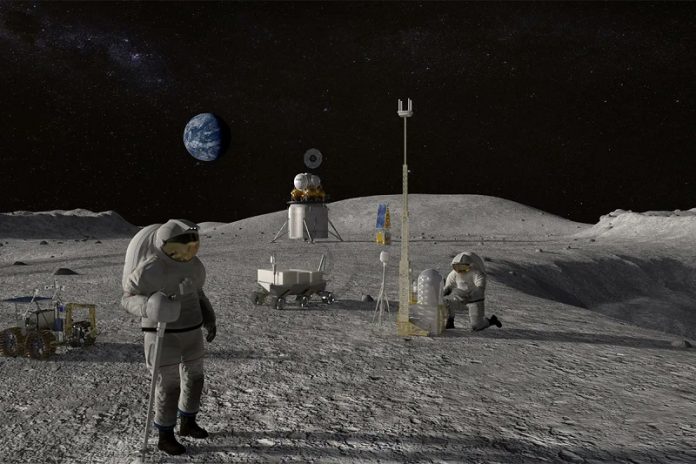

They can also make landing pads on other worlds – at least according to research released by a consortium of scientists at the University of Central Florida, Arizona State University, and Cislune, a private company.

Their research shows how a combination of sorting the lunar soil and then blasting it with microwaves can create a landing pad for future rockets on the Moon – and save any surrounding buildings from being blasted by 10,000 kph dust particles.

This system works in large part because certain minerals on the lunar surface are magnetic, and those same minerals are also very susceptible to being heated up by microwaves.

In particular, a type of glassy mineral called ilmenite, which makes up about 1-2% of the Moon’s surface, is highly magnetic.

Ilmenite forms when the Moon is blasted by small meteors and forms material called agglutinates.

For older lunar soils (i.e., those that haven’t been recently blasted by a meteor), up to 60% of the soil is made up of these agglutinates, whereas only about 20% of “younger” lunar soils are.

So concentrations are high enough in some places that contain significant amounts of older regolith.

So if future explorers wanted to make a landing pad, they could zap this older soil with strong microwaves to sinter it together and create a durable enough surface that would allow a rocket to land on it without sandblasting everything around.

That sandblasting would be particularly wicked as there is no air to slow the dust particles down, as it would on Earth.

The solution seems simple enough – blast the soil with microwaves to sinter it together. However, systems can always be improved, and this microwave sintering process is no exception.

The researchers found that, by subjecting the regolith to a process known as beneficiation, they could increase the amount of microwaves it absorbed and, therefore, the effectiveness of the heating process.

Beneficiation, in this case, involves sifting the soil and hitting it with a magnetic field, causing the more magnetic soil to move toward the magnet, whereas the non-magnetic soil would simply fall back to the ground.

Dr. Phil Metzger, one of the lead authors of the study, compares the process to what recyclers do here on Earth – they sort material by its magnetic strength, allowing magnetic material, such as regular steel, to be separated from the more valuable stainless steel, which is not magnetic.

On the Moon, when the magnet is powered down, the magnetic soil would rest on top of the non-magnetic type.

And since the magnetic soil is also much more susceptible to microwaves, the beneficiation process could increase the amount of energy the material absorbs by 60-80%.

That is an absurd improvement and one that could dramatically decrease the necessary size of the microwave power supply needed for such a mission. Given the weight of some microwave power supplies, any reduction in its heft could dramatically decrease the cost of the overall program.

The paper also looks at other potential landing pad creation methodologies, including polymer-based by paver-based pads.

However, the cost-effectiveness of using in-situ resources, such as those in the microwave sintering project, is the most effective at the current price point of getting equipment into orbit.

While that price might fall significantly in the coming decades, this technique seems like one of the best for the Artemis mission planners that are hoping to land a reusable rocket on the Moon sometime again this decade.

For now, the next research steps would include testing the microwave power source and doing similar tests on the soil in a simulated lunar environment, including in a vacuum.

If some microwaved meals are anything to go by, it might not be the best idea to smell the resulting material though.

Written by Andy Tomaswick.

Source: Universe Today.