The fact that blue jeans typically need only a passing acquaintance with the washing machine has always been a point in their favor.

But even if they rarely see the inside of a laundromat, blue jeans have one of the largest water footprints of any clothing material.

Cotton by nature is an incredibly thirsty crop, and the cotton used to make denim often grows in some of the world’s driest regions.

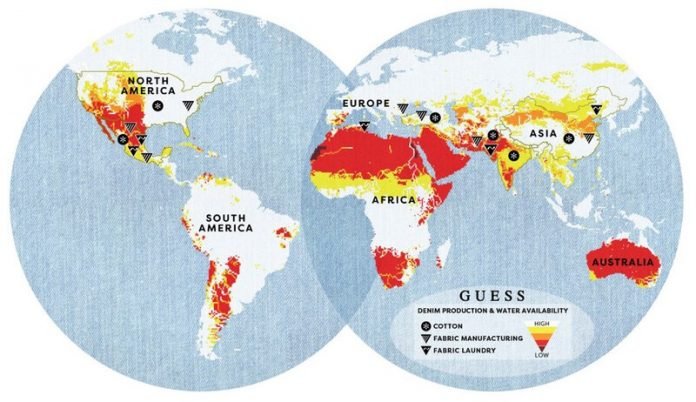

According to a recent study conducted by Robert Vos, assistant professor (teaching) of spatial sciences at the USC, depending on the supply chain, facilities involved in denim manufacturing may be located in “hot spots” — water-scarce areas in which a lot of water is used for textile production.

Such hot spots include regions of India, Pakistan, Mexico and China, as well as parts of California, and the water-intensive activities range from growing the cotton for the denim to laundering the resulting fabric.

“What really surprised me was the magnitude of the differences by space and place — how water-scarce some areas are and how different others are, and how much difference this makes in water calculation,” Vos said.

The study — originally commissioned by Guess Inc., a global blue jeans brand — appeared late last year in the journal Case Studies in the Environment.

It recently won the journal’s 2019 prize for best environmental case study.

Consultation that sprung from a USC connection

When Jaclyn Allen ’16, the director of sustainability at Guess and an alumna of the USC Marshall School of Business, wanted to find someone to analyze water use in her company’s supply chain, she called Vos, with whom she had occasionally discussed sustainability issues while she pursued her MBA.

Vos conducted a “spatially explicit” analysis of the life cycle and water footprint of Guess denim, mapping out water use and identifying hot spots in the company’s production line. Most of the water use came from producing the raw materials — mainly cotton — for the denim.

Allen said Vos’ approach was particularly helpful: Instead of using generalized data gathered from multiple independent locations, he targeted water use and availability for specific sites in the company’s supply chain, giving the company a better view of where it could modify water use.

“By including geographic context in the life cycle analysis of Guess jeans, we created a research outcome with specific, actionable data for our business, and for measurable environmental impact.

My hope is that as life cycle analysis studies become more widespread, geographic considerations will become more widely used, as well,” Allen said.

But changing the denim production cycle is not as easy as it might seem, Vos said. Although he was able to identify “priority facilities” where improving water use would be relatively straightforward, the complexity of today’s global supply chains, with their layers and layers of subcontractors, makes it difficult for a parent company to implement broad, immediate changes.

“By the time you get a piece of apparel there might have been dozens of companies in several countries involved in its production,” he said.

“If the supply chain is that complex, it is very hard for a company to regulate the way the land and water are being used deep in its supply chain.”

There are some changes, however, that Guess has undertaken as a result of Vos’ work, including an increased use of recycled and organic cotton, and the development of zero-cotton denim styles that use wood-based, renewable, sustainably sourced materials.

Careful consumers can help

Despite these obstacles, it is possible to make textile production more sustainable, and many companies have taken steps to do so.

Increased government oversight regarding labeling and standards is ideal, Vos noted, but in its absence there are several nonprofit organizations, such as the Better Cotton Initiative and the Forest Stewardship Council, dedicated to informing consumers about the ecological footprint of a variety of clothing brands.

“There are ways to see if your material is sourced in a way that is more eco-friendly. If you’re looking for a natural material and it has a sustainable sourcing guarantee, that’s a good thing,” Vos said.

While consumer education is part of the solution, Vos added that people ultimately need to take a different approach, both individually and culturally, to shopping and fashion. Unfortunately, the proliferation of cheap clothing has masked the “real” cost — in terms of ecological impact and labor — of many items, he noted.

“In no way are people paying the real costs of these goods,” Vos said. “We’re not paying the cost of the water damage involved in making our jeans in Pakistan or India. If a brand uses synthetic material and it’s contributing to climate change, that cost is not built in.”

Cheap clothing has also led people to view clothing as disposable. “I think our consumer culture is inherently damaging to the environment. People buying new clothes all the time and throwing out clothes after a few wears is very impactful,” Vos added.

Social media may be one of the biggest drivers of this mindset — people are constantly posing in new, fashionable outfits on Instagram, for instance — but social media ultimately could help people shed these attitudes, as well.

Vos cited “buy-nothing” groups and sharing circles on social media as a few ways people can both pool their resources and find support in their decisions to make do with what they have.

Written by Meredith McGroarty.