Since the outbreak of COVID-19, there’s been a worldwide shortage of face masks — particularly, the N95 ones worn by health care workers.

Although these coverings provide the highest level of protection currently available, they have limitations.

Now, researchers reporting in ACS Nano have developed a membrane that can be attached to a regular N95 face mask and replaced when needed.

The filter has a smaller pore size than normal N95 face masks, potentially blocking more virus particles.

N95 masks filter about 85% of particles smaller than 300 nm. SARS-CoV-2 (the coronavirus that causes COVID-19) is in the size range of 65¬–125 nm, so some virus particles could slip through these coverings.

Also, because of shortages, many health care workers have had to wear the same N95 mask repeatedly, even though they are intended for a single use.

To help overcome these problems, Muhammad Mustafa Hussain and colleagues wanted to develop a membrane that more efficiently filters particles the size of SARS-CoV-2 and could be replaced on an N95 mask after every use.

To make the membrane, the researchers first developed a silicon-based, porous template using lithography and chemical etching.

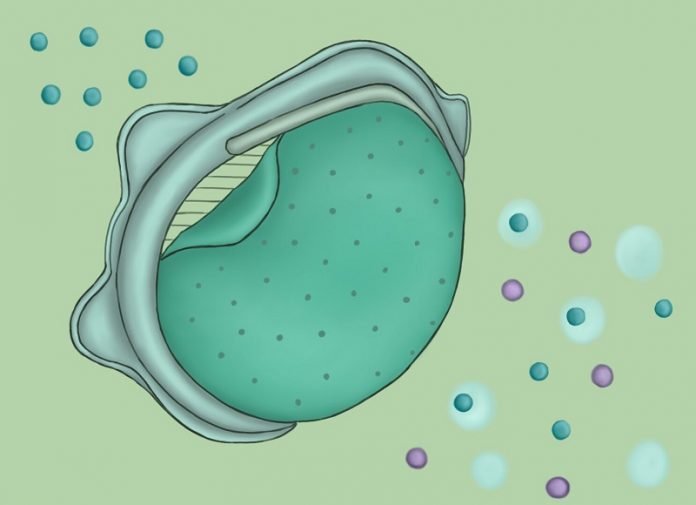

They placed the template over a polyimide film and used a process called reactive ion etching to make pores in the membrane, with sizes ranging from 5–55 nm.

Then, they peeled off the membrane, which could be attached to an N95 mask.

To ensure that the nanoporous membrane was breathable, the researchers measured the airflow rate through the pores.

They found that for pores tinier than 60 nm (in other words, smaller than SARS-CoV-2), the pores needed to be placed a maximum of 330 nm from each other to achieve good breathability.

The hydrophobic membrane also cleans itself because droplets slide off it, preventing the pores from getting clogged with viruses and other particles.

The authors acknowledge funding from the King Abdullah University of Science and Technology Office of Sponsored Research.