Governments, industry, and consumers have faced the issue of counterfeit goods for a long time.

Advancements in technology and growing use of the internet has heightened these potential issues, making it easier for counterfeiters to refine their methods and create additional channels for them to promote and sell their goods.

For those stuck in a prolonged game of ‘cat and mouse’ with criminals, a team of national researchers may have found a solution.

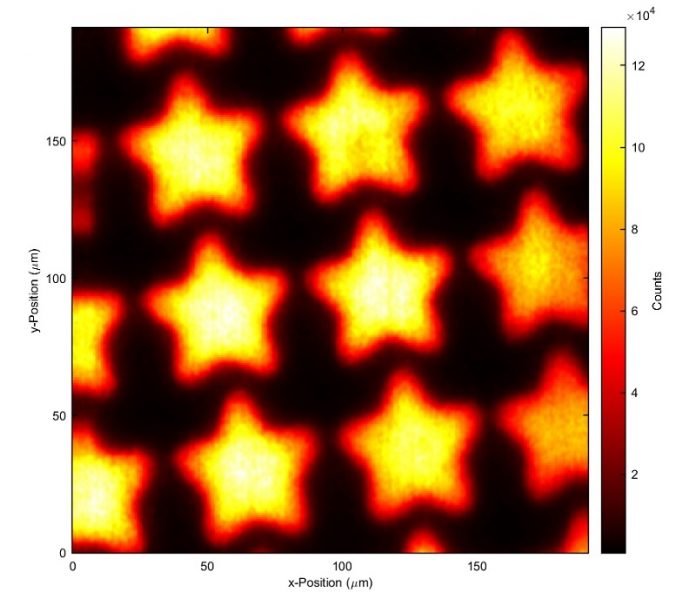

The team, made up of researchers from the University of South Australia, the University of Adelaide, and the University of New South Wales, have found a promising anti-counterfeiting measure through high-density imaging that uses phosphorus nanocrystals to create fluorescent images.

UniSA Research Fellow at the Future Industries Institute, Dr. Nicolas Riesen, is the lead author of the conference paper Ultra-high-resolution fluorescence images in thin phosphor films.

His research has found that exposing certain inorganic nanocrystals to ultraviolet (UV) light will activate the nanocrystals, essentially turning on their fluorescent properties.

When those nanocrystals are exposed to blue light, the regions that have been activated by the UV light will emit red fluorescence light.

“The phosphorous nanocrystals are unique in that they exhibit fluorescence that can be very efficiently switched on or off with a UV light,” Dr. Riesen says.

In essence, this technique presents an exciting opportunity for anti-counterfeiting measures, particularly for those in finance and health.

One of the largest and most dangerous global counterfeiting markets is medicine. The World Health Organization (WHO) estimates that as much as 10 percent of the global pharmaceutical market – a half-trillion-dollar marketplace – is counterfeit.

Meanwhile, the Reserve Bank of Australia typically receives around 30,000 counterfeits every year, at a rate of approximately 15 counterfeits per million genuine banknotes, with an estimated value of $1-2 million.

Dr Riesen says this new method could be used to place small images on banknotes or medical packaging that would be extremely difficult to forge and would be readable with a basic microscope and blue light.

In the paper, the fluorescent images are demonstrated to have ultra-high-resolution, close to the theoretical upper limit of about 25,000 dots per inch (dpi) or 500 line pairs/mm.

The team had been studying these nanocrystal systems for a variety of applications and Dr. Riesen says the small size and resolution of the images present many potential uses.

“Initially we were studying variants of these nanocrystals for optical data storage, as well as x-ray dental imaging at UNSW in Canberra,” Dr Riesen says.

“We then realized that this platform could be used for creating arbitrary fluorescent images on 2D surfaces.

This isn’t limited to banknotes either, for instance, you could also use this technique for putting a stamp on different consumer products, for anti-counterfeiting purposes.”

In terms of the material costs, Dr Riesen says resources needed come at a small cost. Expensive chemicals are not required to make the nanocrystals, rather the difficulty comes in their application.

“You would need specialized people and equipment to put those images on banknotes or consumer products, making it very difficult to counterfeit.

Someone would have to be highly specialised to know how to do this, however, once it’s been set up it’s highly repeatable.”