Anyone who’s ever played the drums, tuned a guitar, or even made a wine glass “sing” by circling a finger along its edge knows about resonance.

Acoustic resonators, like the cavity of a drum or a half-full wine glass, naturally vibrate at certain frequencies of sound waves to produce specific tones.

The phenomenon of resonance can also be applied to light waves, with optical resonators being key components of devices such as lasers and sensors.

A study published in Nature describes a new design for optical resonators that are more effective at trapping light, an important fundamental step towards making more efficient optical devices.

The work was conducted by Bo Zhen and Ph.D. student Jicheng Jin of Penn and researchers at Peking University and MIT.

Part of what makes light so difficult to trap in a resonator is that light is made of high-frequency waves, meaning that their wavelengths are extremely small—millions of times smaller than the acoustic waves people hear every day.

In order to trap these small waves for a long time, optical resonators must be not only incredibly small but also extremely precise.

“The problem is that the fabrication is not perfect,” explains Zhen. “Naturally, the fabrication process will introduce roughness onto the surface and fluctuations to the original design, so the actual device in practice is always bumpy.”

The “bumpy” and imperfect nature of optical resonators is what currently limits a device’s quality factor, or the amount of time that the resonator can trap light before the waves fade away.

Given the limitations in engineering such devices, the researchers sought to make an optical resonator that was less prone to inherent imperfections.

This work was based on Zhen’s prior research on the theory of topological charges, also referred to as bound states in the continuum. Topological charges form by interference, a common wave phenomenon that can be seen when waves crash into one another and either add up to make larger waves or cancel each other out.

Topological charges occur when the radiation waves coming out from the device cancel each other out, enabling the device to contain light’s energy for longer.

With insights from Zhen’s theory, the researchers designed, simulated, and fabricated optical resonator devices called photonic crystal slabs, which are patterned with nanometer-sized holes spaced evenly apart from one another.

Their device was still “imperfect,” with uneven surfaces visible under a scanning electron microscope, but the unique topological feature of the design greatly improved the quality factor, or the ability to trap light for a much longer period of time than otherwise possible.

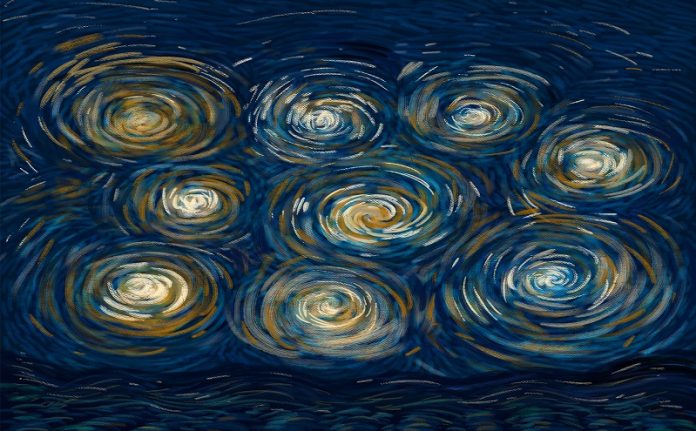

One unique feature of the device is that it could generate nine unique topological charges. Each separate charge then merges into one, causing an even stronger cancellation of the radiation waves, trapping light within the device for longer periods of time.

The merging of the charges was a phenomenon that had been predicted in previous work, explains Zhen, but the group’s latest paper provided a strong theoretical understanding of its effect on quality factors.

“The fact that they have nine charges merging at the same point is a very unique feature. At first it is quite misleading; you can interpret it in different ways, and we were sidetracked towards some other directions. Eventually, through a lot of thinking, everything worked out.”

Their innovative platform, with a quality factor 10 times greater than other devices that don’t use merging topological charges, can lead to improvements in numerous optics-based applications.

Furthermore, the researchers already demonstrated the usability of their approach on an immediate real-world application, as the study looked at wavelengths of light that are already being used for telecommunication.

Thanks to their complementary areas of expertise, from device fabrication at Peking University and theoretical physics at Penn, the scientists were able to develop a simple, physics-based solution to a previously unsolved engineering challenge.

“It improves the quality without optimizing fabrication,” says Jin, who recently earned his master’s degree from Peking University and is now a graduate student in Zhen’s lab.

“You don’t have to do demanding work to improve the fabrication methods; you just need to choose a smart design. There are no complicated tricks, but you can see a really great improvement.”

Written by Erica K. Brockmeier.