A new concept for an aluminium battery has twice the energy density as previous versions, is made of abundant materials, and could lead to reduced production costs and environmental impact.

The idea has potential for large scale applications, including storage of solar and wind energy.

Researchers from Chalmers University of Technology, Sweden, and the National Institute of Chemistry, Slovenia, are behind the idea.

Using aluminium battery technology could offer several advantages, including a high theoretical energy density, and the fact that there already exists an established industry for its manufacturing and recycling.

Compared with today’s lithium-ion batteries, the researchers’ new concept could result in markedly lower production costs.

“The material costs and environmental impacts that we envisage from our new concept are much lower than what we see today, making them feasible for large scale usage, such as solar cell parks, or storage of wind energy, for example,” says Patrik Johansson, Professor at the Department of Physics at Chalmers.

“Additionally, our new battery concept has twice the energy density compared with the aluminium batteries that are ‘state of the art’ today.”

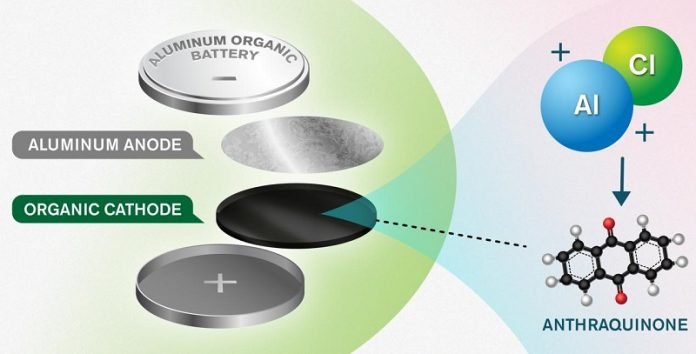

Previous designs for aluminium batteries have used the aluminium as the anode (the negative electrode) – and graphite as the cathode (the positive electrode).

But graphite provides too low an energy content to create battery cells with enough performance to be useful.

But in the new concept, presented by Patrik Johansson and Chalmers, together with a research group in Ljubljana led by Robert Dominko, the graphite has been replaced by an organic, nanostructured cathode, made of the carbon-based molecule anthraquinone.

The anthraquinone cathode has been extensively developed by Jan Bitenc, previously a guest researcher at Chalmers from the group at the National Institute of Chemistry in Slovenia.

The advantage of this organic molecule in the cathode material is that it enables storage of positive charge-carriers from the electrolyte, the solution in which ions move between the electrodes, which make possible higher energy density in the battery.

“Because the new cathode material makes it possible to use a more appropriate charge-carrier, the batteries can make better usage of aluminium’s potential. Now, we are continuing the work by looking for an even better electrolyte.

The current version contains chlorine – we want to get rid of that,” says Chalmers researcher Niklas Lindahl, who studies the internal mechanisms which govern energy storage.

So far, there are no commercially available aluminium batteries, and even in the research world they are relatively new. The question is if aluminium batteries could eventually replace lithium-ion batteries.

“Of course, we hope that they can. But above all, they can be complementary, ensuring that lithium-ion batteries are only used where strictly necessary. So far, aluminium batteries are only half as energy dense as lithium-ion batteries, but our long-term goal is to achieve the same energy density.

There remains work to do with the electrolyte, and with developing better charging mechanisms, but aluminium is in principle a significantly better charge carrier than lithium, since it is multivalent – which means every ion ‘compensates’ for several electrons.

Furthermore, the batteries have the potential to be significantly less environmentally harmful,” says Patrik Johansson.