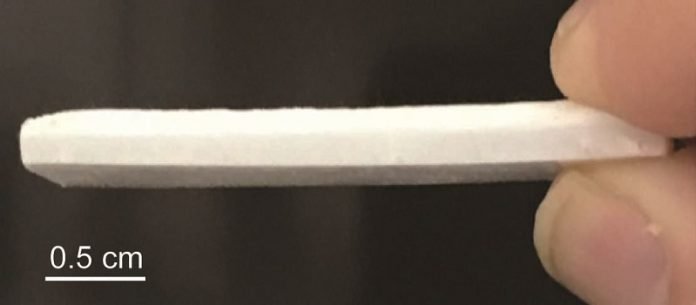

A new lightweight plastic that is 14 times stronger and eight times lighter (less dense) than steel may lead to next-generation military armor.

Round, smooth and iridescent, pearls are among the world’s most exquisite jewels; now, these gems are inspiring a U.S. Army research project to improve military armor.

By mimicking the outer coating of pearls (nacre, or as it’s more commonly known, mother of pearl), researchers at University at Buffalo, funded by the Army Research Office (ARO), created a lightweight plastic that is 14 times stronger and eight times lighter (less dense) than steel and ideal for absorbing the impact of bullets and other projectiles.

ARO is an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory.

The research findings are published in the journal ACS Applied Polymer Materials, and its earlier publication in J. Phys. Chem. Lett. (see related links below)

“The material is stiff, strong and tough,” said Dr. Shenqiang Ren, professor in the Department of Mechanical and Aerospace Engineering, a member of University of Buffalo’s RENEW Institute, and the paper’s lead author.

“It could be applicable to vests, helmets and other types of body armor, as well as protective armor for ships, helicopters and other vehicles.”

The bulk of the material is a souped-up version of polyethylene (the most common plastic) called ultrahigh molecular weight polyethylene, or UHMWPE, which is used to make products like artificial hips and guitar picks.

When designing the UHMWPE, the researchers studied mother of pearl, which mollusks create by arranging a form of calcium carbonate into a structure that resembles interlocking bricks.

Like mother of pearl, the researchers designed the material to have an extremely tough outer shell with a more flexible inner backing that’s capable of deforming and absorbing projectiles.

“Professor Ren’s work designing UHMWPE to dramatically improve impact strength may lead to new generations of lightweight armor that provide both protection and mobility for Soldiers,” said Dr. Evan Runnerstrom, program manager, materials design, ARO.

“In contrast to steel or ceramic armor, UHMWPE could also be easier to cast or mold into complex shapes, providing versatile protection for Soldiers, vehicles, and other Army assets.”

This is what’s known as soft armor, in which soft yet tightly woven materials create what is essentially a very strong net capable of stopping bullets. KEVLAR is a well-known example.

The material the research team developed also has high thermal conductivity. This ability to rapidly dissipate heat further helps it to absorb the energy of bullets and other projectiles.

The team further experimented with the UHMWPE by adding silica nanoparticles, finding that tiny bits of the chemical could enhance the material’s properties and potentially create stronger armor.

“This work demonstrates that the right materials design approaches have the potential to make big impacts for Army technologies,” Runnerstrom said.