In a new study, researchers have developed a new technology to help remove oil traces in produced water.

The new technology could help clean and purify water used in oil refinement.

The study was done by a group of researchers from Purdue University.

Every day more than 2 billion gallons of produced water is generated in the United States.

Produced water is a byproduct from the oil refinery and extraction process.

It has been a big challenge in the oil refinery industry because the water contains contaminants and is not safe for household and commercial use.

Current methods to remove traces of contaminants from water are expensive and energy-intensive.

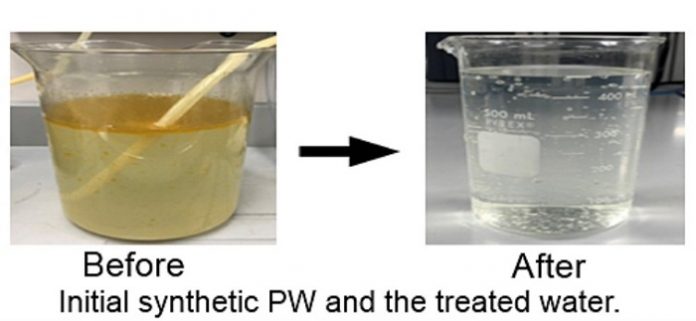

To solve the problem, the researchers have created a new method to remove nearly all traces of oil in produced water.

It uses activated charcoal foam and subjects it to solar light to produce heat and purify the water. The charcoal foam can absorb the oil contaminants from the water.

Moreover, water produced with the new method meets all EPA standards for clean water from industrial sources.

Another advantage of the method is that 95% of the oil absorbed by the foam can be recovered efficiently.

This method can be integrated with current disposal systems to purify a large amount of water. It can help reduce the current stress on water grids.

The team believes their method is a simple, clean and inexpensive treatment process. This is the first-of-its-kind method to do water purification in a single step.

Now the team is working with the Purdue Research Foundation Office of Technology Commercialization to patent the innovation. They hope to find partners to continue developing it.

One author is Ashreet Mishra, a graduate research assistant at the Purdue University Northwest Water Institute.

The study was presented at the annual conference for the Produced Water Society.

Copyright © 2019 Knowridge Science Report. All rights reserved.